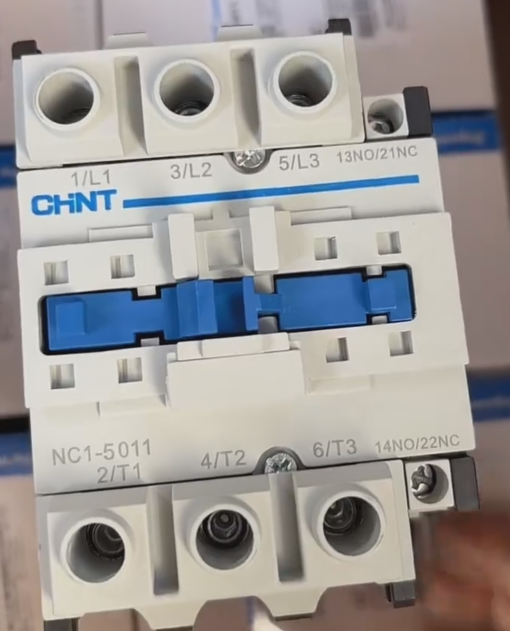

Chint DC Contactor NC1-5011-36V

Product description

Chint (CHNT) **NC1-5011-36V** is a commonly used DC contactor, belonging to the NC1 series, suitable for remote control in industrial control circuits and frequent operation of loads such as motors. The detailed information is as follows:

1. Basic Product InformationChint NXR series thermal overload relays price

- **Brand**: Chint (CHNT)

- **Series**: NC1 series AC contactor

- **Model**: NC1-5011-36VCHINT circuit breaker price

- **Function**: Used to control the on-off of three-phase motors or other loads, with overload and short-circuit protection functions.

2. Core Parameters

Main Circuit ParametersCHINT surge protector price

- **Rated Current**: 50A (Under the AC-3 usage category, suitable for motor control)

- **Number of Poles**: 3 poles (main contacts) + 1 normally open auxiliary contact + 1 normally closed auxiliary contact

- **Rated Voltage**:

- Main contacts: AC 380V (default), optional 220V/660V, etc.

- Coil voltage: DC 36V (The "36V" in the model indicates that the coil control voltage is 36V DC)

Control Circuit Parameters

- **Coil Power Consumption**: Approximately 7VA (energized) / 2VA (holding)

- **Mechanical Life**: More than 10 million times

- **Electrical Life**: More than 1 million times under the AC-3 usage category

3. Technical Characteristics

- **Arc Extinguishing Method**: Clay arc extinguishing cover, effectively extinguishes the arc and ensures safety.

- **Protection Level**: IP20 (Prevents finger contact, dust-proof)

- **Wiring Method**:

- Main contacts: Screw connection (Supports multi-strand or single-strand wires)

- Auxiliary contacts: Insertion or screw connection

- **Installation Method**:

- 35mm DIN rail installation (Standard industrial rail)

- Base installation (Optional)

4. Application Scenarios

- **Motor Control**: Suitable for the start-stop control of three-phase asynchronous motors below 50A, such as fans, water pumps, conveyors, etc.

- **Automation System**: As an executive element of PLC or other controllers, to achieve automated control.

- **Industrial Power Distribution**: Used to control other loads such as lighting and heaters.

5. Precautions

- **Coil Voltage Matching**: It is necessary to ensure that the control power supply voltage is consistent with the rated coil voltage (36V DC) to avoid burning the coil.

- **Load Type**: Select the usage category (such as AC-1, AC-3, etc.) according to the nature of the load. AC-3 is suitable for direct starting of motors.

- **Ambient Temperature**: The normal operating temperature range is -5°C to +40°C. If it exceeds this range, it needs to be derated for use.

- **Installation Direction**: It needs to be installed vertically, and the inclination should not exceed 5°.

6. Certifications and Standards

- **Certifications**: CCC (China Compulsory Certification), CE, RoHS, etc.

- **Compliance Standards**: GB 14048.4, IEC 60947-4-1.

7. Matching Suggestions

- **Thermal Relay**: It is recommended to match with Chint JR36 series thermal relays (such as JR36-63) to provide overload protection.

- **Fuse**: Optional Chint NT series fuses (such as NT00-50A) to provide short-circuit protection.

Summary

Chint NC1-5011-36V is a reliable industrial-grade AC contactor, suitable for application scenarios with a DC control voltage of 36V, especially for the control of small and medium-sized motors. When purchasing or using it, attention should be paid to coil voltage matching, load type, and environmental conditions to ensure safe and reliable operation.

The following are typical application cases of Chint **NC1-5011-36V** AC contactor, sorted out in combination with its technical characteristics and industry requirements:

1. Industrial Automation Production Line

Case Scenario

In the assembly line of an automobile parts factory, NC1-5011-36V is used to control the start and stop of the conveyor belt motor. In cooperation with PLC (such as Chint NX series), the following functions are achieved:

- **Remote Control**: The PLC sends a 36V DC signal to trigger the contactor, precisely controlling the operation and stop of the conveyor belt.

- **Overload Protection**: Matched with Chint JR36 series thermal relays, it monitors the motor current in real-time. When the load exceeds 50A, it automatically cuts off the power supply to avoid motor burnout.

- **Multi-machine Linkage**: Multiple contactors work together to achieve synchronous start and stop of multiple conveyor belts, improving production efficiency.

Technical Advantages

- **High Reliability**: The clay arc extinguishing cover effectively extinguishes the arc, adapting to the industrial environment with frequent start and stop.

- **Flexible Expansion**: 1 normally open + 1 normally closed auxiliary contact can feedback the motor status to the PLC, facilitating fault diagnosis.

2. Chemical and Petrochemical Industry

Case Scenario

In the raw material conveying system of a petrochemical enterprise, NC1-5011-36V is used to control the centrifugal pump motor:

- **Explosion-proof Environment Adaptation**: Although the module itself has an IP20 protection level, it can meet the safety requirements of the petrochemical industry by being installed in an explosion-proof distribution box and cooperating with explosion-proof motors.

- **Remote Monitoring**: Integrated with the DCS system, it can remotely adjust the running status of the pump, and at the same time, feedback the start and stop signals of the pump to the central control room through the auxiliary contacts of the contactor.

- **Energy-saving Control**: According to the signal of the pipeline pressure sensor, it automatically starts and stops the pump to avoid idling or overload, reducing energy consumption.

Technical Advantages

- **Wide Voltage Adaptation**: The coil voltage of 36V DC supports a fluctuation of ±20%, adapting to the unstable industrial power grid scenarios.

- **Long Life Design**: The mechanical life exceeds 10 million times, reducing the maintenance frequency and being suitable for chemical equipment with continuous operation.

3. Fire Pump Control System

Case Scenario

In the fire protection system of a commercial complex, NC1-5011-36V serves as the executive element of the fire pump:

- **Emergency Start**: When the fire alarm system is triggered, a 36V DC signal activates the contactor to force the start of the fire pump to ensure the supply of fire extinguishing water.

- **Redundancy Design**: A configuration of one in use and one standby for double pumps is adopted. The contactor cooperates with NH40 series isolating switches to achieve automatic switching of the main and standby power supplies.

- **Fault Diagnosis**: The auxiliary contacts are connected to the fire alarm controller to monitor the running status of the pump in real-time. When there is an abnormality, it emits sound and light alarms.

Technical Advantages

- **High Response Speed**: The coil energizing time is < 20ms, meeting the requirements of the fire protection system for quick start.

- **Impact Current Resistance**: The rated current of 50A can withstand the instantaneous large current impact when the fire pump starts.

4. Agricultural Irrigation System

Case Scenario

In the drip irrigation system of a farm, NC1-5011-36V is used to control the submersible pump motor:

- **Automated Control**: Through the linkage with soil moisture sensors and PLC, when the humidity is lower than the threshold, it automatically starts the water pump to achieve precise irrigation.

- **Energy-saving Mode**: According to the size of the irrigation area, the combination operation of multiple water pumps is switched through the contactor to avoid the waste of energy caused by the idling of high-power water pumps.

- **Overload Protection**: The thermal relay cooperates with the contactor to prevent the motor from being damaged due to blockage or dry running of the water pump.

Technical Advantages

- **Environmental Adaptability**: The operating temperature range is -5°C to +40°C, suitable for outdoor agricultural environments.

- **Low Power Consumption Design**: The coil holding power consumption is only 2VA, reducing the long-term operating power consumption.

5. Textile Machinery Drive

Case Scenario

In the loom control system of a textile factory, NC1-5011-36V is used to control the main shaft motor:

- **Frequent Start and Stop**: Cooperate with the frequency converter to achieve quick start, stop and speed adjustment of the loom, adapting to the weaving needs of different fabrics.

- **Signal Feedback**: The auxiliary contacts feedback the motor status to the textile machinery controller to ensure the continuity of the weaving process.

- **Convenient Maintenance**: The design of detachable spring terminals makes it convenient to replace the contactor, reducing downtime.

Technical Advantages

- **Vibration Resistance**: The modular structure and sturdy shell design can withstand the high-frequency vibration during the operation of textile machinery.

- **Long Electrical Life**: The electrical life reaches 1 million times under the AC-3 usage category, suitable for the high-intensity use of textile machinery.

6. Packaging Equipment Control

Case Scenario

In a food packaging production line, NC1-5011-36V is used to control the servo motor of the packaging machine:

- **Precise Positioning**: In cooperation with PLC and servo driver, it realizes the precise conveying and cutting of packaging materials.

- **Safety Interlock**: When the equipment door is opened or the emergency stop button is triggered, the contactor immediately cuts off the motor power to ensure the safety of operators.

- **Quick Response**: The short coil energizing time ensures the synchronism and high efficiency of packaging actions.

Technical Advantages

- **High Reliability**: Certified by CE and RoHS, it meets the safety standards of the food industry.

- **Compact Design**: With a width of 45mm, it saves space in the control cabinet and is suitable for small packaging equipment.

Summary

Chint NC1-5011-36V contactor, with its characteristics such as **36V DC control, large current capacity of 50A, and high reliability**, is widely used in industrial automation, chemical, fire protection, agriculture, textile, packaging and other fields. Its core values lie in:

1. **Safety Protection**: Cooperate with thermal relays and fuses to provide overload, short-circuit and phase-loss protection.

2. **Flexible Control**: Support remote control and signal feedback of systems such as PLC and DCS.

3. **Environmental Adaptation**: Wide temperature range and anti-vibration design, suitable for harsh industrial environments.

For more specific configuration solutions, it is recommended to combine the actual load characteristics (such as motor power, starting current) and system requirements.