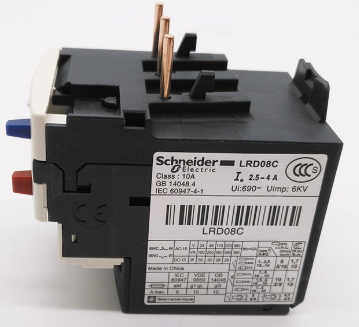

Schneider LRD08C thermal relay

Product description

The Schneider LRD08C thermal relay is a classic product in the TeSys D series, specifically designed to provide reliable overload and phase-loss protection for AC motors. The following details cover technical parameters, operation guidelines, application scenarios, and maintenance recommendations:

Core Technical Parameters and Structural Design

1. Key Parameters Schneider low-voltage molded case circuit breaker EZD100B3015MAN

- **Setting Current Range**: 2.5–4A, suitable for motors with rated currents within this range (e.g., 2.2kW/380V motors).

- **Rated Voltage**: AC24–380V, compatible with common industrial voltage levels.

- **Trip Class**: Class 10A, ensuring rapid response to overloads (tripping within ≤2 minutes at 1.5x setting current).

- **Wiring Methods**: Supports screw terminals, spring terminals, and EverLink quick wiring to meet diverse installation needs.

2. Structure and Component Functions

- **Ir Setting Knob**: White dial with scales for precise adjustment of the setting current; lead-seal hook design prevents misoperation. Schneider low-voltage molded case circuit breaker

- **Trip Indicator**: A toggle window displays the "T" mark to intuitively indicate fault status.

- **Reset Control**: Manual (H)/automatic (A) reset selector switch (automatic reset requires removing the protective cover); the blue button resets faults, and the red button serves as an emergency stop control.

- **Differential Phase-Loss Protection**: Triggered within 0.5 seconds during phase loss via a differential amplification mechanism of inner/outer push rods, protecting motors from single-phase operation damage.

Installation and Commissioning Guidelines

1. Installation Steps Schneider-MCCB-NSX250F-4P-250A*

- **Mechanical Installation**: Supports DIN rail (35mm) or screw fixing; can be directly assembled with TeSys D contactors to form compact motor starters.

- **Electrical Connections**:

- **Main Circuit**: Connect L1/L2/L3 terminals of the thermal relay to the contactor outlet, and T1/T2/T3 to the motor windings.

- **Control Circuit**: Series normally closed contacts (95–96) into the contactor coil circuit; normally open contacts (97–98) can be used for signal feedback.

2. Setting Current Adjustment Schneider Circuit Breakers Price*

- **Initial Setting**: Rotate the Ir knob to the corresponding scale based on the motor's rated current (e.g., set to 3.2 for a 3.2A motor).

- **Verification Test**: Simulate overload using the test button, and observe whether the contactor trips and resets to ensure action values meet requirements.

Faut Diagnosis and Maintenance

1. Common Fault Troubleshooting

- **Frequent Tripping*Chint's NB1-63DC series DC circuit breakers Price*

- Check if the motor is overloaded or blocked, and measure whether the actual current exceeds the setting value.

- Confirm if loose terminal connections cause excessive contact resistance.

- **No Tripping**:

- Check if the test button fails or if the bimetallic strip deforms due to long-term overload.

- Inspect the control circuit for open circuits or damaged contactor coils.

- **Phase-Loss Protection Failure**:

- Clean dust from the differential mechanism to ensure smooth push rod movement.

2. Maintenance Recommendations

- **Regular Cleaning**: Use a dry cloth to remove dust from the housing and terminals, preventing heat dissipation issues from dust accumulation.

- **Contact Inspection**: Check the contact resistance of normally closed contacts annually (should be ≤50mΩ); polish oxidation layers with fine sandpaper if necessary.

- **Environmental Check**: Ensure the installation temperature ranges from -5°C to +55°C and humidity ≤95% without condensation.

Typical Application Scenarios

1. Industrial Machinery

- **Machine Tool Spindle Motors**: Prevents overheating from excessive cutting loads.

- **Textile Machinery**: Protects winding motors from overload due to sudden changes in yarn tension.

2. Fluid Conveying Systems

- **Centrifugal Pumps**: Quickly cuts off power when pump impellers are blocked or pipeline resistance is abnormal.

- **Air Compressors**: Prevents motors from continuous overload during air leakage or excessive pressure.

3. Fans and Ventilation Equipment

- **Axial Fans**: Provides protection when air ducts are blocked or motor bearings age.

Selection and Matching Recommendations

1. Compatible Contactors

- Recommended to pair with LC1-D09~LC1-D18 series contactors to ensure interface compatibility and synchronous operation.

- Example: For a 3kW motor, use an LC1-D12 contactor + LRD08C thermal relay combination.

2. Coordination with Circuit Breakers

- Upstream circuit breakers (e.g., NSX series) should have a rated current ≥1.5x the motor's rated current and breaking capacity ≥ the line short-circuit current.

3. Purchase Channels and Price Reference

- **Dealer Network**: Contact via Whatsapp: 0086-13811255435.

Precautions

1. Reset Operation Specifications

- For manual reset, wait for the bimetallic strip to cool (about 2 minutes) before pressing the blue button to avoid misoperation.

- In automatic reset mode, ensure the control circuit is re-energized after fault elimination to resume operation.

2. Environmental Adaptability

- In high-vibration environments (e.g., construction machinery), use EverLink terminals to enhance connection reliability.

- When the altitude exceeds 2000 meters, derate the current (e.g., adjust a 3A setting to 2.7A).

3. Alternative Model Reference

- For higher-precision protection, consider upgrading to the TeSys T series (e.g., LRD08C corresponds to the T series model LRD08C), supporting Modbus communication and overload curve programming.

Through the above detailed instructions, users can comprehensively master the technical characteristics, operation key points, and maintenance methods of the LRD08C, ensuring it plays a stable and reliable protective role in industrial control scenarios. In practical applications, it is recommended to combine Schneider's official video tutorials and user manuals for installation and commissioning, and contact technical support for customized solutions when necessary.