control panel for Chint inverters

Product description

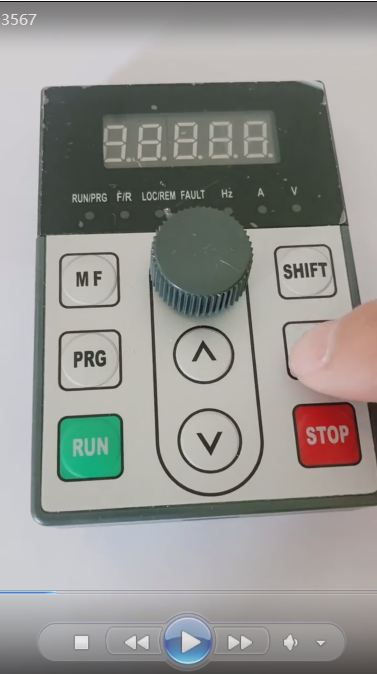

The design of the control panel for Chint inverters aims to provide an intuitive operating experience and efficient parameter configuration. The panel functions of different series and models vary slightly, but the core operating logic and basic functions are common.

I. Core Functions and Operations of the Control Panel

1. **Display and Navigation*Chint moulded case circuit breaker*

Most models are equipped with an LED display, which can real-time display operating status (such as output frequency, voltage, current), parameter settings, and fault codes. For example, the NIO1 series adopts a large-size LED screen that supports multi-parameter switching display, while the NVF2 series is equipped with a detachable keyboard to support remote monitoring. The panel usually includes the following buttons:

- **Navigation keys**: Used for menu switching and parameter adjustment (such as up and down arrow keys).

- **Function keys**: Including run (RUN), stop (STOP), confirm (ENTER), reset (RESET), etc.

- **Potentiometer/knob**: Some models (such as NVF2G) are equipped with an analog knob, which can directly adjust the frequency setting value.Schneider-MCCB-NSX250F-4P-250A

2. **Parameter Setting and Function Configuration**

The core parameters of the inverter can be accessed through the panel, such as:

- **Basic parameters**: Rated voltage, current, power, etc. (need to match the motor).

- **Control parameters**: Acceleration/deceleration time, running direction, V/F curve type (such as linear type, torque reduction curve).

- **Advanced functions**: Vector control mode (SVC), PID adjustment, multi-speed operation, communication protocol (such as Modbus), etc.Schneider Circuit Breakers Price

- **Fault diagnosis**: View fault codes through the panel (such as 0C3 indicating constant speed overcurrent, E001 indicating overcurrent protection), and troubleshoot according to the instructions in the manual.

3. **Trial Operation and Debugging**

Taking the NVFM5 series as an example, the trial operation steps are as follows:

- **No-load test**: Disconnect the motor load, start the inverter through the panel, and observe whether the output frequency is stable.

- **Load test**: After connecting the motor, gradually increase the frequency, and check whether the motor rotation direction, noise, and temperature rise are normal.

- **Parameter optimization**: If the motor runs abnormally, the "motor self-learning" function (such as in the NVF2 series) can be used to automatically match parameters.

II. Common Faults and Countermeasures

1. **Overcurrent/overload fault**

- **Causes**: Sudden load change, low grid voltage, too small power selection of the inverter.

- **Countermeasures**: Check the load connection, confirm the stability of the input voltage; if the protection is triggered frequently, a larger power model needs to be replaced.

2. **Overheat protection**

- **Causes**: High ambient temperature, failure of the cooling fan, or blockage of the air duct.

- **Countermeasures**: Clean the dust on the radiator to ensure good ventilation in the installation environment; check whether the fan is running normally.

3. **Communication fault**

- **Causes**: Poor line contact, mismatched protocol parameters, or damaged communication module.

- **Countermeasures**: Check whether the terminal blocks are loose, confirm that the communication protocol settings (such as baud rate, slave address) are consistent with the upper computer; replace the communication module if necessary.

4. **Key failure or no display on the panel**

- **Causes**: Hardware failure, incorrect parameter setting, or power supply problem.

- **Countermeasures**: Try to reset the parameters (such as long-pressing the RESET key); if it is invalid, contact after-sales to inspect the control panel or replace spare parts.

III. Model Differences and Featured Functions

1. **NVF2 series**

- **Detachable keyboard**: Supports remote installation, convenient for operation outside the control cabinet.

- **Simple PID control**: Built-in constant pressure water supply sleep function, suitable for municipal water supply and other scenarios.

2. **NVF3 series**

- **Vector control**: Supports sensorless vector control (SVC), achieving high-precision torque control (150% rated torque at 0.5Hz).

- **Multi-language menu**: Provides Chinese and English operation interfaces, adapting to international applications.

3. **NVFM5 series**

- **Three-level menu mode**: Simple type (basic parameters), custom type (special functions), engineering type (full parameters), meeting different user needs.

- **Anti-interference design**: Built-in anti-harmonic circuit, adapting to the complex electromagnetic environment of industrial sites.

4. **NVF2G series (2025 version)**

- **Intelligent current limiting**: Automatically suppresses overcurrent faults and improves system stability.

- **Wide voltage input**: Supports 380V±15% voltage fluctuation, adapting to areas with unstable power grids.

IV. Operation Suggestions and Safety Tips

1. **Parameter initialization**

It is recommended to restore the factory settings for new machines or after maintenance (such as resetting through F14.12=1 in the NVFM5 series), and then reconfigure the parameters according to actual needs.

2. **Safety regulations**

- Disconnect the power supply and wait for 10 minutes before operation to ensure that the DC bus voltage is below 25V.

- It is strictly forbidden to touch the terminals or perform hardware maintenance when the inverter is running.

3. **Environmental adaptation**

- The installation environment should be dry and ventilated, avoiding direct sunlight and corrosive gases.

- Derating is required when the altitude exceeds 1000 meters (1% derating for every 100 meters increase).

- Some models (such as NVF3) provide multi-language manuals, which can be obtained through the "Document Download" section on the official website.

2. **After-sales support**

- Global customers can contact me via Whatsapp: 0086-13811255435

- Users in North America can get support through Chint Mexico subsidiary or local distributors, and specific contact information can be found on the official website.

3. **Video tutorials**

- www.transformerandswitchgear.com

VI. Extended Functions and Advanced Applications

1. **Communication and networking**

It supports Modbus, Profibus and other protocols, and can set communication parameters (such as baud rate, data bit) through the panel to realize linkage control with PLC or upper computer.

2. **Energy management**

Some models (such as NVF2G) have built-in energy-saving algorithms, which can automatically adjust operating parameters according to the load to reduce energy consumption.

3. **Industry customization**

For industries such as textiles and papermaking, special functions (such as swing frequency control, multi-speed cycle) are provided, and preset parameter groups can be quickly called through the panel.

By rationally using the functions of the control panel, users can efficiently complete the debugging, monitoring and maintenance of the inverter. In case of complex problems, it is recommended to refer to the official manual or contact technical support first to ensure the stable operation of the system.