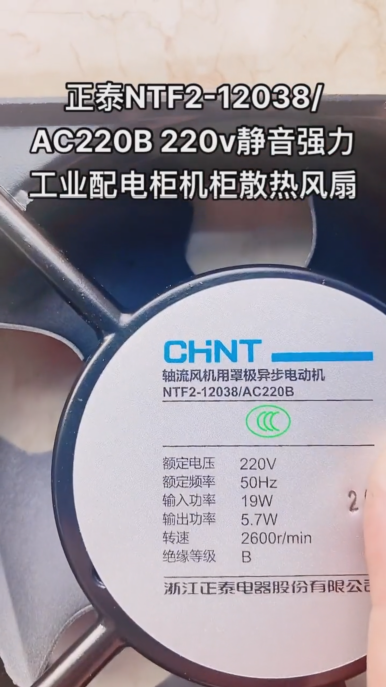

Chint NTF2-12038/AC220 cooling fan

Product description

The Chint NTF2-12038/AC220 cooling fan is an axial flow fan specially designed for industrial environments, suitable for ventilation and heat dissipation needs of equipment such as electrical cabinets and distribution boxes:

I. Product Specifications and Performance

1. **Basic Parameters**

- **Dimensions**: 120mm × 120mm × 38mm (width × height × thickness), in line with industrial standard installation dimensions.

- **Voltage/Frequency**: AC220V/50Hz, compatible with power grid standards in China and most countries.

- **Power and Rotational Speed**: Power is 16W, rotational speed is 2600 RPM, and air volume can reach 144 CFM (about 245 m³/h), balancing heat dissipation efficiency and energy consumption.

- **Noise Control**: The operating noise is 39 dB, with a silent design, suitable for work environments sensitive to noise.

2. **Bearing Types and Service Life**

- **Ball Bearing (model suffix B)**: Has a long service life of up to 50,000 hours, resistant to high and low temperatures (-30℃ ~ +65℃), suitable for long-term high-load operation.

- **Oil-Impregnated Bearing (model suffix S)**: Has lower noise (about 31 dB) but a shorter service life (30,000 hours). It needs regular lubricating oil replenishment and is applicable to a temperature range of -10℃ ~ +60℃.

3. **Environmental Adaptability**

- Operating altitude ≤ 2000 meters, pollution degree 2, and can operate stably in general industrial environments.

- The protection level is not clearly marked, but the material is flame-retardant plastic, which has a certain anti-corrosion ability.

II. Application Scenarios

1. **Core Uses**

- Forced heat dissipation of electrical cabinets and distribution boxes to prevent internal components from aging due to overheating.

- Ventilation systems of mechanical equipment (such as electric welders, CNC machine tools) to maintain a stable operating temperature.

- Auxiliary heat dissipation of communication equipment and server cabinets to ensure the stability of data transmission.

2. **Installation Suggestions**

- Sufficient space (recommended ≥ 10cm) should be reserved around the fan to avoid air flow blockage affecting heat dissipation efficiency.

- Installation should be carried out by professionals to ensure firm wiring and avoid poor contact due to vibration.

III. Purchase and Maintenance

1. **Price and Channels**

- **Ball bearing model**: The unit price is about 100-132 yuan.

- **Oil-impregnated bearing model**: The unit price is about 80-110 yuan.

- Pay attention to distinguishing the model suffixes (B for ball bearing, S for oil-impregnated bearing) to avoid confusion.

2. **Maintenance Points**

- **Ball bearing**: No regular lubrication is needed, but the dust on the blades should be cleaned every six months to prevent air volume attenuation.

- **Oil-impregnated bearing**: It is recommended to drop sewing machine oil or special lubricant into the bearing every 3 months to extend the service life.

- If the fan speed drops abnormally, it may be due to capacitor failure or bearing wear, and the corresponding components should be replaced in time.

IV. Notes

1. **Safety Specifications**

- It is strictly forbidden to use in flammable, explosive and humid environments to avoid the risk of short circuit.

- Do not touch the fan blades during operation to prevent mechanical injury.

2. **Compatibility Check**

- Confirm that the equipment voltage is consistent with the fan specification (AC220V) to avoid burning the motor.

- Measure the installation hole distance (120mm × 120mm, hole diameter φ5.5mm) before installation to ensure it matches the cabinet.

With the characteristics of high air volume, low noise and long service life, this fan has become one of the mainstream choices for industrial heat dissipation. Users can choose the bearing type according to specific needs (such as budget, noise requirements) and purchase through regular channels to ensure genuine products and after-sales support.

The specific parameters of the Chint NTF2-12038/AC220 cooling fan are as follows, sorted out in combination with official data and industry standards to ensure the accuracy and practicability of the data:

I. Core Performance Parameters

1. **Basic Electrical Parameters**

- **Rated Voltage**: AC220V (±10% fluctuation range, i.e., 198-242V)

- **Frequency**: 50Hz

- **Rated Current**: 0.12A (the same for ball/oil-impregnated bearing models)

- **Input Power**: 16W (16W for both bearing types)

- **Starting Voltage**: ≥187V (in line with industrial standards, ensuring stable start-up under grid fluctuations)

2. **Mechanical Parameters**

- **Dimensions**: 120mm × 120mm × 38mm (width × height × thickness)

- **Installation Hole Distance**: 120mm × 120mm, hole diameter φ5.5mm, suitable for 8-M5 screw fixing

- **Weight**: About 1kg (material is flame-retardant ABS plastic)

- **Bearing Types**:

- **Ball Bearing (suffix B)**: Service life of 50,000 hours, temperature resistance of -30℃ ~ +65℃

- **Oil-Impregnated Bearing (suffix S)**: Service life of 30,000 hours, temperature resistance of -10℃ ~ +60℃

3. **Heat Dissipation Performance**

- **Rotational Speed**: 2600 RPM (constant speed design to ensure stable air volume)

- **Air Volume**: 440 m³/h (144 CFM), meeting the forced heat dissipation needs of scenarios such as electrical cabinets

- **Air Pressure**: 7.0 mm-H₂O (ball bearing), which can overcome the resistance of short pipes or grilles

- **Noise Control**:

- Ball bearing: 39 dB(A)

- Oil-impregnated bearing: 31 dB(A)

II. Environmental Adaptability Parameters

1. **Protection Level**: The IP level is not clearly marked, but it has passed pollution degree 2 (IEC 60664-1) and installation category Ⅱ/Ⅲ certification, suitable for general industrial environments and can resist dust and vertically dripping liquids.

2. **Altitude Limit**: ≤2000 meters (to ensure stable motor insulation performance).

3. **Humidity Range**: ≤95%RH (no condensation).

4. **Insulation Class**: Class F (155℃), in line with GB/T 14048.1 standard, with better temperature resistance than ordinary Class B insulation.

III. Certification and Compliance

1. **Industry Certification**: In line with GB/T 14048.11 (low-voltage switchgear and controlgear) and GB/T 10178 (industrial fan performance test) standards.

2. **Environmental Requirements**: Passed RoHS certification, free of lead, mercury and other harmful substances.

3. **Explosion-Proof Characteristics**: Non-explosion-proof design, only for non-flammable and explosive environments.

IV. Installation and Maintenance Parameters

1. **Wiring Method**: 3-core wire (L/N/PE), wire diameter 0.75mm², standard length 1.5 meters.

2. **Vibration Level**: ≤5.0 mm/s (in line with ISO 14694 industrial fan vibration standards).

3. **Maintenance Cycle**:

- Ball bearing: Clean the dust on the blades every six months, no lubrication needed.

- Oil-impregnated bearing: Replenish sewing machine oil every 3 months (2-3 drops each time).

V. Key Comparative Parameters

| Parameter | Ball Bearing (B) | Oil-Impregnated Bearing (S) |

| Noise | 39 dB(A) | 31 dB(A) |

| Service Life | 50,000 hours | 30,000 hours |

| Temperature Range | -30℃~+65℃ | -10℃~+60℃ |

| Applicable Scenarios | Long-term high-load operation | Low-noise sensitive environments |

| Price | About 100-132 yuan/unit | About 80-110 yuan/unit |

VI. Notes

1. **Compatibility Check**:

- Confirm that the equipment voltage is consistent with the fan to avoid motor burnout due to overvoltage.

- Measure the cabinet hole distance before installation to ensure the 120mm × 120mm installation position matches.

2. **Safety Specifications**:

- It is forbidden to use in humid environments (humidity > 95%) or environments with high dust concentration.

- Do not touch the fan blades during operation; it is recommended to install a protective net.

3. **Troubleshooting**:

- If the air volume drops sharply, check whether the blades are dusty or the bearings are stuck.

- When the noise increases abnormally, it is better to replace the bearing first rather than the whole machine.