Time Relay ERV-08

The Time Relay ERV-08 is a multifunctional timing control device launched by Hebei Zhaoneng Electric Co., Ltd. (Latham), mainly used in scenarios such as industrial automation and power-off control of commercial billboards. The following is its core information and application guidelines:

I. Core Parameters and Functions

1. **Technical Specifications**

- **Brand and Model**: Latham ERV-08. It is an imported product and supports 2P rail installation.

- **Rated Voltage**: Commonly AC 220V (needs to be confirmed according to the specific model).

- **Delay Range**: The adjustable range is usually from 0.1 second to several hours, suitable for timing requirements in different scenarios.

- **Contact Types**: It has normally open (NO) and normally closed (NC) contacts, and supports single-pole double-throw (SPDT) or double-pole double-throw (DPDT) configurations.

- **Working Modes**: It supports "on-delay" (the contacts act with a delay after the coil is energized) or "off-delay" (the contacts reset with a delay after the coil loses power). The specific mode needs to be set according to the model.

2. **Functional Features**

- **High-precision Control**: Adopting electronic delay technology, the error rate is as low as ±1%, ensuring accurate timing.

- **Rail Installation**: With a standard 35mm DIN rail design, it is convenient for quick installation and maintenance.

- **LED Indicator Lights**: Display the power status and delay progress, facilitating troubleshooting.

- **Wide Voltage Input**: Some models support a wide voltage range of AC 100-240V, adapting to the power grid environments in different regions.

II. Typical Application Scenarios

1. **Industrial Automation**

- **Motor Control**: Used for star-delta step-down starting, sequential start and stop, etc., to avoid current surges.

- **Timed Start and Stop of Conveyor Belts**: Control the running time of conveyor belts in the production line to optimize logistics efficiency.

- **Equipment Protection**: Cooperate with sensors to achieve delayed shutdown of equipment in case of overload or failure, reducing losses.

2. **Commercial and Civil Use**

- **Timed Switching of Billboards**: Automatically control the power on/off of billboards according to day and night or business hours.

- **Lighting System**: Used for the delayed turning on or off of streetlights and landscape lights to save energy.

- **Security System**: Link with cameras or alarm devices to achieve delayed alarm after intrusion detection.

3. **Special Scenarios**

- **Water Treatment Equipment**: Control the start and stop time of water pumps to achieve automatic water replenishment or drainage.

- **Laboratory Equipment**: Timely start/stop experimental instruments to ensure the standardization of the experimental process.

III. Installation and Wiring Guidelines

1. **Physical Installation**

- **Rail Fixing**: Snap the ERV-08 onto the 35mm DIN rail to ensure that the buckle is firm.

- **Environmental Requirements**: The installation location should have good ventilation, and avoid high-temperature, humid or dusty environments. The recommended working temperature is from -10°C to +50°C.

2. **Electrical Wiring**

- **Power Connection**: Connect the AC 220V power cord to the coil pins (usually pins 1-2), and pay attention to distinguish between the neutral wire and the live wire.

- **Load Connection**:

- **Normally Open Contact (NO)**: Closes with a delay, and is used to control devices that need delayed start (such as motors).

- **Normally Closed Contact (NC)**: Opens with a delay, and is used to control devices that need delayed shutdown (such as lighting).

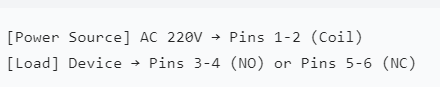

- **Example Wiring Diagram**:

The Time Relay ERV-08 is a multifunctional timing control device launched by Hebei Zhaoneng Electric Co., Ltd. (Latham), mainly used in scenarios such as industrial automation and power-off control of commercial billboards. The following is its core information and application guidelines:

I. Core Parameters and Functions

1. **Technical Specifications**

- **Brand and Model**: Latham ERV-08. It is an imported product and supports 2P rail installation.

- **Rated Voltage**: Commonly AC 220V (needs to be confirmed according to the specific model).

- **Delay Range**: The adjustable range is usually from 0.1 second to several hours, suitable for timing requirements in different scenarios.

- **Contact Types**: It has normally open (NO) and normally closed (NC) contacts, and supports single-pole double-throw (SPDT) or double-pole double-throw (DPDT) configurations.

- **Working Modes**: It supports "on-delay" (the contacts act with a delay after the coil is energized) or "off-delay" (the contacts reset with a delay after the coil loses power). The specific mode needs to be set according to the model.

2. **Functional Features**

- **High-precision Control**: Adopting electronic delay technology, the error rate is as low as ±1%, ensuring accurate timing.

- **Rail Installation**: With a standard 35mm DIN rail design, it is convenient for quick installation and maintenance.

- **LED Indicator Lights**: Display the power status and delay progress, facilitating troubleshooting.

- **Wide Voltage Input**: Some models support a wide voltage range of AC 100-240V, adapting to the power grid environments in different regions.

II. Typical Application Scenarios

1. **Industrial Automation**

- **Motor Control**: Used for star-delta step-down starting, sequential start and stop, etc., to avoid current surges.

- **Timed Start and Stop of Conveyor Belts**: Control the running time of conveyor belts in the production line to optimize logistics efficiency.

- **Equipment Protection**: Cooperate with sensors to achieve delayed shutdown of equipment in case of overload or failure, reducing losses.

2. **Commercial and Civil Use**

- **Timed Switching of Billboards**: Automatically control the power on/off of billboards according to day and night or business hours.

- **Lighting System**: Used for the delayed turning on or off of streetlights and landscape lights to save energy.

- **Security System**: Link with cameras or alarm devices to achieve delayed alarm after intrusion detection.

3. **Special Scenarios**

- **Water Treatment Equipment**: Control the start and stop time of water pumps to achieve automatic water replenishment or drainage.

- **Laboratory Equipment**: Timely start/stop experimental instruments to ensure the standardization of the experimental process.

III. Installation and Wiring Guidelines

1. **Physical Installation**

- **Rail Fixing**: Snap the ERV-08 onto the 35mm DIN rail to ensure that the buckle is firm.

- **Environmental Requirements**: The installation location should have good ventilation, and avoid high-temperature, humid or dusty environments. The recommended working temperature is from -10°C to +50°C.

2. **Electrical Wiring**

- **Power Connection**: Connect the AC 220V power cord to the coil pins (usually pins 1-2), and pay attention to distinguish between the neutral wire and the live wire.

- **Load Connection**:

- **Normally Open Contact (NO)**: Closes with a delay, and is used to control devices that need delayed start (such as motors).

- **Normally Closed Contact (NC)**: Opens with a delay, and is used to control devices that need delayed shutdown (such as lighting).

- **Example Wiring Diagram**: - **Precautions**:

- The load current shall not exceed the rated capacity of the contacts (usually 5A).

- Avoid common grounding of the coil and the load to prevent interference.

IV. Operation and Settings

1. **Adjustment of Delay Time**

- **Knob/Dial Switch**: Set the delay time through the knob or dial switch on the panel. The units are usually seconds (s), minutes (min) or hours (h).

- **Reset Function**: Some models support a manual reset button, which can immediately terminate the delay process.

2. **Mode Switching**

- **On-delay**: After the coil is energized, the contacts act with a delay; after the coil loses power, the contacts reset immediately.

- **Off-delay**: After the coil is energized, the contacts act immediately; after the coil loses power, the contacts reset with a delay.

- **Cyclic Delay**: Some high-end models support periodic cyclic delay, which needs to be set through programming.

V. Troubleshooting and Maintenance

1. **Common Problems and Solutions**

- **Contacts Do Not Act**: Check whether the power supply is normal, whether the coil is burned out, and whether the delay setting is correct.

- **Inaccurate Delay**: Calibrate the time setting, or replace the backup battery (if available).

- **Contact Adhesion**: Clean the oxidation layer of the contacts, or replace the relay.

2. **Maintenance Suggestions**

- **Regular Inspection**: Check the wear condition of the contacts every quarter and clean the dust in a timely manner.

- **Avoid Overload**: Ensure that the load current is within the rated range to prevent contact erosion.

- **Spare Parts**: It is recommended to stock relays of the same model for quick replacement.

VI. Suppliers and Alternative Models

1. **Domestic Supplier**

Hebei Zhaoneng Electric Technology Co., Ltd. www.transformerandswitchgear.com

2. **Alternative Models**

- **Omron H3CR Series**: High-precision time relays that support multiple delay modes.

- **Schneider LRN Series**: Thermal overload relays, which can replace some control requirements (pay attention to the functional differences).

VII. Safety Precautions

- **Power-off Operation**: Be sure to cut off the power supply before wiring or maintenance to avoid the risk of electric shock.

- **Load Matching**: Select a suitable relay according to the power of the equipment to prevent fire caused by overload.

- **Electromagnetic Interference**: Keep away from strong magnetic field equipment such as frequency converters and transformers to avoid signal interference.

For more detailed technical parameters or customized solutions, it is recommended to directly contact the manufacturer or distributor to obtain the product manual.

- **Precautions**:

- The load current shall not exceed the rated capacity of the contacts (usually 5A).

- Avoid common grounding of the coil and the load to prevent interference.

IV. Operation and Settings

1. **Adjustment of Delay Time**

- **Knob/Dial Switch**: Set the delay time through the knob or dial switch on the panel. The units are usually seconds (s), minutes (min) or hours (h).

- **Reset Function**: Some models support a manual reset button, which can immediately terminate the delay process.

2. **Mode Switching**

- **On-delay**: After the coil is energized, the contacts act with a delay; after the coil loses power, the contacts reset immediately.

- **Off-delay**: After the coil is energized, the contacts act immediately; after the coil loses power, the contacts reset with a delay.

- **Cyclic Delay**: Some high-end models support periodic cyclic delay, which needs to be set through programming.

V. Troubleshooting and Maintenance

1. **Common Problems and Solutions**

- **Contacts Do Not Act**: Check whether the power supply is normal, whether the coil is burned out, and whether the delay setting is correct.

- **Inaccurate Delay**: Calibrate the time setting, or replace the backup battery (if available).

- **Contact Adhesion**: Clean the oxidation layer of the contacts, or replace the relay.

2. **Maintenance Suggestions**

- **Regular Inspection**: Check the wear condition of the contacts every quarter and clean the dust in a timely manner.

- **Avoid Overload**: Ensure that the load current is within the rated range to prevent contact erosion.

- **Spare Parts**: It is recommended to stock relays of the same model for quick replacement.

VI. Suppliers and Alternative Models

1. **Domestic Supplier**

Hebei Zhaoneng Electric Technology Co., Ltd. www.transformerandswitchgear.com

2. **Alternative Models**

- **Omron H3CR Series**: High-precision time relays that support multiple delay modes.

- **Schneider LRN Series**: Thermal overload relays, which can replace some control requirements (pay attention to the functional differences).

VII. Safety Precautions

- **Power-off Operation**: Be sure to cut off the power supply before wiring or maintenance to avoid the risk of electric shock.

- **Load Matching**: Select a suitable relay according to the power of the equipment to prevent fire caused by overload.

- **Electromagnetic Interference**: Keep away from strong magnetic field equipment such as frequency converters and transformers to avoid signal interference.

For more detailed technical parameters or customized solutions, it is recommended to directly contact the manufacturer or distributor to obtain the product manual.