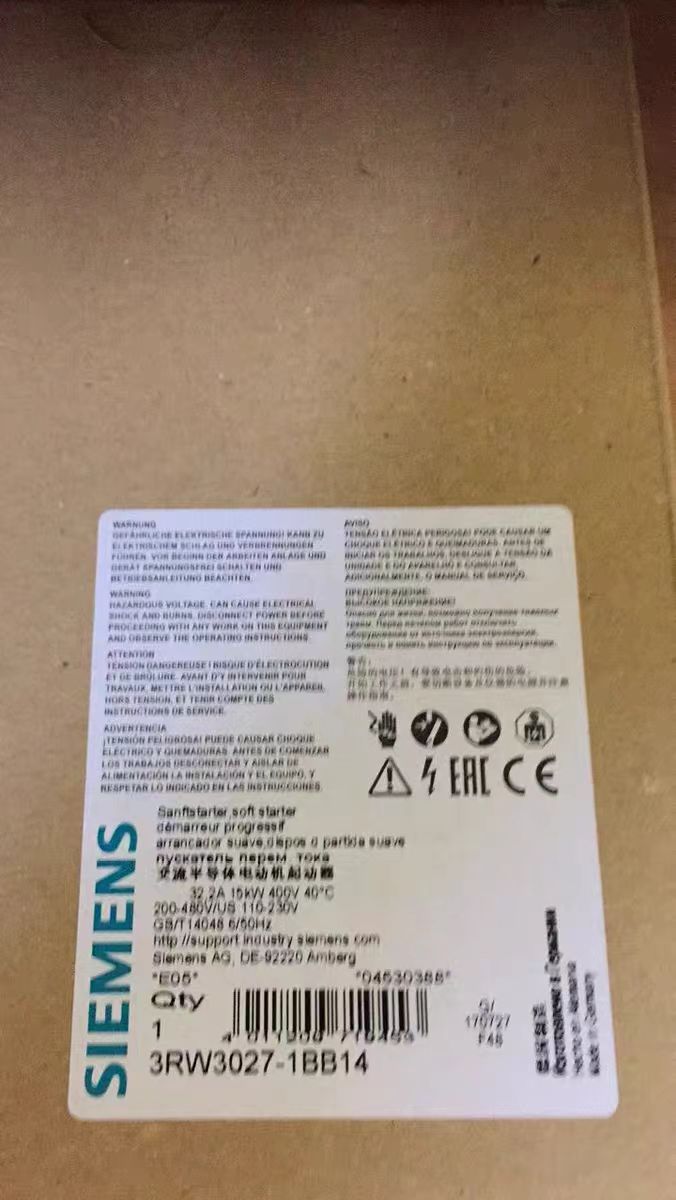

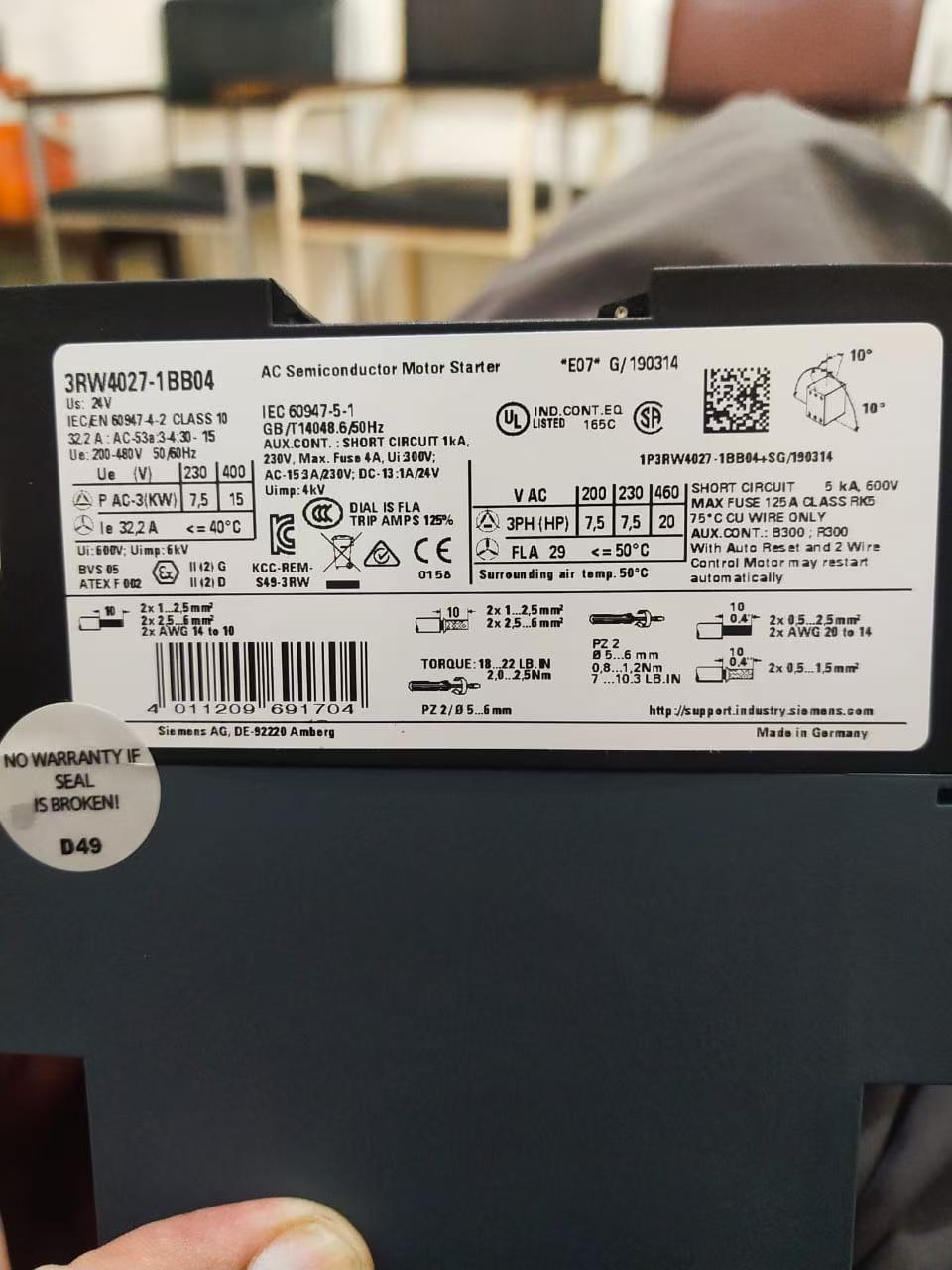

Siemens 3RW4027-1BB04

Product description

is a **compact soft starter** in the SIRIUS series, mainly used for the smooth starting and stopping control of AC motors. It is suitable for scenarios such as industrial automation, pump equipment, conveyor belts, mixers, etc. The following is its core information and application guidelines:

is a **compact soft starter** in the SIRIUS series, mainly used for the smooth starting and stopping control of AC motors. It is suitable for scenarios such as industrial automation, pump equipment, conveyor belts, mixers, etc. The following is its core information and application guidelines:

I. Core Technical Parameters

- **Type**: SIRIUS soft starter (Model 3RW4027-1BB04)

- **Rated Current**: 32A (Suitable for a 15kW motor at 400V)

- **Voltage Range**: 200-480V AC (Supports wide voltage input)

- **Control Voltage**: 24V AC/DC (Connected via screw terminals)

- **Dimensions**: 45mm wide × 125mm high × 155mm deep (IP20 protection level)

- **Starting Modes**:

- **Voltage Ramp Starting**: Gradually increase the motor voltage to reduce mechanical shock.

- **Current Limiting Starting**: Protect the motor and the power grid by setting the maximum starting current.

- **Protection Functions**:

- Overload protection (Built-in thermal overload relay)

- Short-circuit protection (Inherent characteristics of thyristors)

- Under-voltage/Over-voltage protection

- Phase sequence monitoring

- **Communication Interface**: Supports Modbus RTU (Requires an external communication module). Parameters can be configured and diagnosed through Siemens TIAPortal software.

II. Typical Application Scenarios

1. **Pump Equipment**: Avoid the water hammer effect and extend the pipeline life.

2. **Conveyor Belt System**: Reduce mechanical wear and reduce the impact of the starting current on the power grid.

3. **Fans and Compressors**: Start smoothly and reduce maintenance costs.

4. **Milling Machines and Mixers**: Support frequent starting and stopping and adapt to high-load requirements.

5. **Industrial Automation**: Integrated into the PLC control system to achieve remote monitoring and fault diagnosis.

YouTube:https://youtube.com/shorts/D7tE4RhkMAw

III. Product Features and Advantages

1. **Compact Design**: The 45mm width saves space in the control cabinet and supports side-by-side installation.

2. **Flexible Configuration**:

- The starting time (0.1-60 seconds) and starting voltage (10-100% of the rated voltage) can be set.

- Built-in bypass contactor (S0 size) to reduce operating power consumption.

3. **Intelligent Diagnosis**:

- Four LED indicators display the operating status (such as power supply, fault, overload).

- Supports reading real-time current, voltage, temperature and other data through the communication interface.

4. **Reliability**:

- The thyristor module has passed strict tests and is suitable for harsh environments (-20°C to +60°C).

- Complies with RoHS and CE certifications, and the built-in EMC filter reduces electromagnetic interference.

IV. Installation and Commissioning

1. **Wiring Requirements**:

- Main circuit: Connect the motor and the power supply (It is recommended to use a 6mm² cable).

- Control circuit: Connect the 24V AC/DC power supply to terminals 1 and 2, and connect the start/stop signals to terminals 3 and 4.

2. **Parameter Settings**:

- Configure through Siemens TIAPortal software or the local operation panel (Requires external connection).

- Typical parameters: Set the starting time to 10 seconds and the current limit to 3 times the rated current.

3. **Troubleshooting**:

- **Common Problems**:

- **Starting Failure**: Check the power supply voltage, motor wiring, and parameter settings.

- **Overload Alarm**: Confirm whether the load is too heavy or adjust the overload protection threshold.

- **Communication Failure**: Check the communication cable, module address, and baud rate settings.

- **Indicator Light Status**:

- **Green Flashing**: Starting.

- **Yellow On Steadily**: Equipment overheating or fault.

- **Red On Steadily**: Emergency stop or short-circuit protection triggered.

V. Lifecycle and Alternative Models

- **Current Status**: PM 300 (Active product), still in production and sales.

- **Alternative Models**:

- **3RW44 Series**: High-performance soft starter, supporting a larger power range (15-1200kW), with more built-in communication interfaces.

- **G120 Inverter**: Suitable for scenarios that require speed regulation function, but the cost is higher.

VI. Support Resources

1. **Document Download**:

commissioning guide).

2. **Technical Support**:

- Siemens Industrial Support Center: Provides online Q&A, firmware updates, and fault diagnosis services.

- Local agents: Such as Automation24 (Europe), Alibaba (China), where you can consult about prices and delivery times.

VII. Precautions

1. **Environmental Requirements**:

- Avoid installing in a humid, dusty or high-temperature environment. It is recommended to install it vertically.

- Keep the surrounding air circulating to ensure good heat dissipation.

2. **Safety Specifications**:

- Disconnect the power supply during installation and follow electrical safety standards.

- Regularly check the tightness of the terminals to prevent overheating caused by looseness.

3. **Compatibility**:

- It needs to be used in conjunction with a circuit breaker (such as the 3NP1 series) to ensure short-circuit protection.

- If communicating with a PLC, the corresponding communication module (such as CP340/CP341) needs to be configured.

VIII. Typical Cases

- **Conveyor Belt System Upgrade**: A steel plant used 3RW4027-1BB04 in the conveyor belt renovation. Through the current limiting starting function, the motor wear was reduced. At the same time, the built-in diagnosis function was used to monitor the operating status in real time, reducing the failure rate by 30%.

- **Pump Energy-saving Renovation**: In the municipal water supply system, the soft starter avoided the water hammer effect through the voltage ramp starting, extended the pipeline life, and saved about 15% of energy consumption every year.

For further information on the specific applications or alternative solutions of this model, it is recommended to visit [Siemens Industrial Mall] or contact the local technical support.