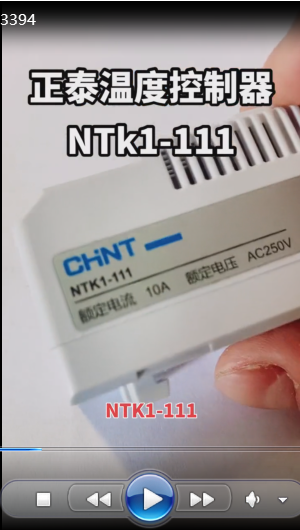

Chint Temperature Controller NTK1-111

Product description

Functional Features

- **Temperature Control**: It can be connected to a heater, and when the temperature reaches the set value, the circuit will be disconnected to prevent overheating; it can also be used to monitor the filter fan. When the temperature exceeds the set value, the circuit will be closed to output a signal and start the fan for heat dissipation.Chint AC Contactor

- **Mode Switching**: It supports both manual adjustment and automatic adjustment modes, which can be flexibly switched according to actual needs. It also has a temperature memory function, which can remember commonly used temperature settings.

- **Remote Control and Energy Saving**: It supports remote control via mobile APP, allowing users to adjust the temperature anytime and anywhere. At the same time, it has an energy-saving mode, which can automatically adjust the working state of the heater according to the ambient temperature to achieve energy conservation and emission reduction.

Technical ParametersCHINT Contactor NC1-09

- **Contact Capacity**: 10A@250VAC, 15A@120VAC, 30WDC@(24~72)VDC.

- **Temperature Range**: Three temperature ranges are available, namely 0℃~60℃, -10℃~50℃, and 20℃~80℃.

- **Contact State**: Single control NO (normally open), single control NC (normally closed), double control NO+NC (normally open + normally closed).Schneider-MCCB-NSX250F-4P-250A

- **Other Parameters**: The ambient temperature is -20℃~80℃; the relative atmospheric humidity does not exceed 50% when the ambient air temperature is +40℃, and higher relative humidity is allowed at lower temperatures, such as up to 90% at +20℃; the pollution degree is level 2; the installation category is Ⅱ and Ⅲ; the switching temperature tolerance is ±7K.

Installation and Use

- **Installation Conditions**: It is installed using TH35-7.5 type mounting rail, and the inclination of the mounting surface from the vertical plane does not exceed 5°.

- **Wiring Method**: Single control (NC) can be connected to the heater, single control (NO) can be connected to the fan, and double control (NO+NC) can be connected to both the heater and the fan to achieve more complex control functions.

Application ScenariosSchneider Circuit Breakers Price

- **Household Scenarios**: It can be used to control household appliances such as electric heaters and air conditioners to keep the indoor temperature comfortable. It can also be remotely controlled through a mobile APP to adjust the indoor temperature in advance before returning home.

- **Industrial Field**: It is suitable for various industrial equipment that requires temperature control, such as industrial ovens, heating furnaces, control cabinets, etc., to ensure that the equipment operates within the normal temperature range and improve the stability and service life of the equipment.

- **Commercial Places**: Such as air conditioning systems and ventilation systems in shopping malls, hotels, office buildings, etc. The NTK1-111 temperature controller can achieve precise temperature control, providing a comfortable environment for customers and employees.

Chint temperature controllers (represented by the NTK1 series, including NTK1-111) may have some common faults during use. The following are specific fault phenomena, possible causes and solutions:

1. **Abnormal temperature display (such as inaccurate display, jumping or no display)**

- **Fault Phenomena**:

- The displayed temperature deviates greatly from the actual ambient temperature;

- The displayed value jumps frequently;

- There is no display on the screen at all.

- **Possible Causes**:

1. Poor contact or damage of the temperature sensor;

2. Loose internal wiring or falling off solder joints of the controller;

3. Unstable or disconnected power supply voltage;

4. Fault of the display screen itself.

- **Solutions**:

1. Check whether the sensor wiring is firm, re-plug or replace the sensor (need to match the same model and specification);

2. After power off, open the controller shell, check the internal wiring connection, and tighten the loose terminals;

3. Use a multimeter to measure whether the power supply voltage is within the rated range (such as AC220V) to ensure normal power supply;

4. If the above steps are ineffective, it may be a display screen fault, and you need to contact after-sales service to replace the controller.

2. **Failure to control the load normally (such as the fan/heater not starting or stopping)**

- **Fault Phenomena**:

- When the set temperature is reached, the load (fan/heater) does not start or stop as expected;

- The load runs all the time or does not run at all.

- **Possible Causes**:

1. Incorrect setting of temperature parameters (such as the set value is reversed from the actual demand);

2. Adhesion or damage of the output contacts (relays);

3. Open circuit or short circuit of the load line;

4. Fault of the internal control chip of the controller.

- **Solutions**:

1. Re-check and adjust the set temperature (refer to the operation steps in the manual), and confirm whether the "normally open/normally closed" mode matches the load (such as the fan is connected to NO, and the heater is connected to NC);

2. After power off, use a multimeter to measure the on-off state of the output terminals. If the contacts are stuck (always on or off), the relay or controller needs to be replaced;

3. Check whether the load (fan/heater) line is broken or short-circuited, repair the line or replace the load;

4. If the above steps are ineffective, it may be a fault of the control chip, contact after-sales service for maintenance or replacement.

3. **Frequent tripping or burning of the controller**

- **Fault Phenomena**:

- Frequent triggering of leakage protection or air switch tripping after being connected to the circuit;

- The controller shell becomes hot, smokes or burns.

- **Possible Causes**:

1. The load power exceeds the rated capacity of the controller (such as NTK1-111 is rated at 10A@250VAC, and overloading is easy to burn);

2. Incorrect wiring (such as live wire and neutral wire reversed, short circuit);

3. Too high ambient temperature (exceeding the upper limit of the controller's working environment of 80℃);

4. Quality problems of the controller itself (such as internal short circuit).

- **Solutions**:

1. Confirm whether the load power is within the rated range of the controller. If overloaded, replace it with a controller with larger capacity or add an intermediate relay;

2. Re-check the wiring according to the manual to ensure that the live wire, neutral wire and load wire are connected correctly without short circuit;

3. Improve the ventilation and heat dissipation of the installation environment, and avoid the controller being in a high-temperature environment for a long time (such as keeping away from heat sources);

4. If the above factors are excluded, it may be a product quality problem, and you can contact after-sales service for return or exchange within the warranty period.

4. **Key failure or inability to save parameters**

- **Fault Phenomena**:

- No response when pressing the adjustment key;

- After setting parameters and powering off and restarting, the parameters return to default values.

- **Possible Causes**:

1. The key surface is stained or oxidized;

2. The internal battery (if with memory function) is dead;

3. Fault of the memory chip.

- **Solutions**:

1. Wipe the key surface with a dry cloth. If it still fails, the key may be oxidized internally and needs to be disassembled for cleaning or replaced;

2. Some models rely on built-in batteries to save parameters. If the parameters cannot be saved, the same type of battery can be replaced (needs to be operated by professionals);

3. If it is a fault of the memory chip, contact after-sales service for maintenance or replacement of the controller.