GCS low voltage switchgear

Product description

GCS AC low voltage withdrawable switchgear

GCS AC low voltage withdrawable switchgear

**I. Definition and Functions**

1. **Definition**

- The GCS AC low-voltage withdrawable switchgear is suitable for low-voltage power distribution systems with a three-phase AC frequency of 50Hz (or 60Hz), a rated working voltage of 380V (or 400V), 660V, and a rated current of 4000A or less. It is a switchgear that combines various low-voltage electrical components such as busbars, circuit breakers, contactors, thermal relays, and fuses, and can realize functions such as power distribution, control, protection, and monitoring.

2. **Functions**

- **Power distribution**

- Reasonably distribute the low-voltage electric energy from the transformer and transmit it to different branches or load equipment. For example, in a large shopping mall, the electric energy of the total incoming line can be distributed to the lighting, air conditioning, elevators and other electrical equipment on different floors and areas.

- **Circuit control**

- Realize the start-stop control of the circuit by controlling the on-off of electrical components such as circuit breakers and contactors. For example, the start and stop of a certain production line in a workshop can be controlled. When production is needed, the circuit is connected, and after production is completed, the circuit is disconnected.

- **Protection function**

- It has multiple protection functions such as overload protection, short-circuit protection, and undervoltage protection. When an overload occurs in the circuit, the thermal relay will act automatically and cut off the circuit to protect the equipment; when a short circuit occurs, the fuse or circuit breaker will quickly disconnect the circuit to prevent the fault from expanding; undervoltage protection can prevent the equipment from being damaged due to abnormal operation when the voltage is too low.

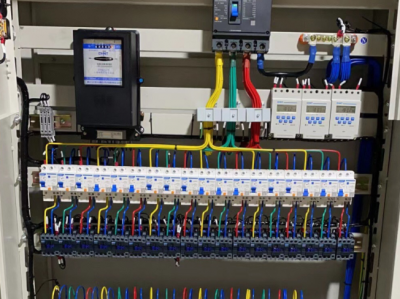

- **Monitoring function**

- With the help of measuring instruments such as ammeters, voltmeters, and electric energy meters, real-time monitoring of parameters such as current, voltage, and electric energy in the circuit is carried out. Operation and maintenance personnel can timely discover abnormal conditions in the circuit through monitoring data. For example, excessive current may indicate potential overload or short-circuit hazards in the circuit.

**II. Structural Composition**

1. **Cabinet body**

- **Frame structure**:

The cabinet frame is made of 8MF open-section steel, which is processed and bent by numerical control equipment and has high strength and precision. This structure is convenient for assembly and expansion, and the size and internal layout of the cabinet can be flexibly adjusted according to user needs.

- **Protection level**:

The protection level is generally IP30 and above, which can effectively prevent solid foreign matters with a diameter greater than 2.5mm from entering the cabinet and protect internal electrical components from dust, small animals and other intrusions. The surface of the cabinet is usually treated by electrostatic spraying and has good anti-corrosion performance.

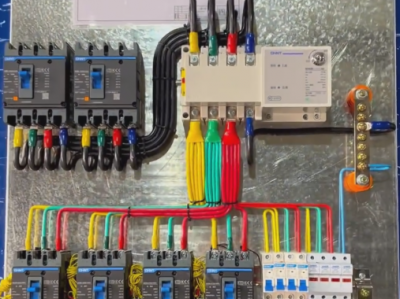

- **Partition form**:

The inside of the cabinet adopts a functional unit design and is divided into different compartments such as a busbar compartment, a functional unit compartment (drawer compartment), and a cable compartment. Each compartment is isolated from each other to improve the safety and reliability of the equipment.

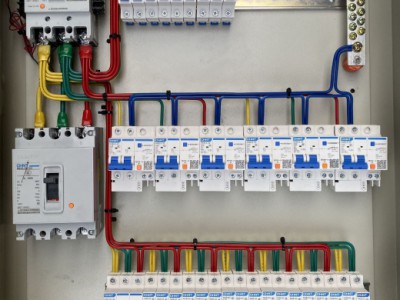

2. **Electrical components**

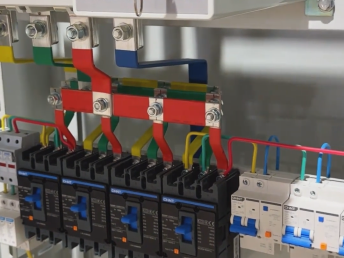

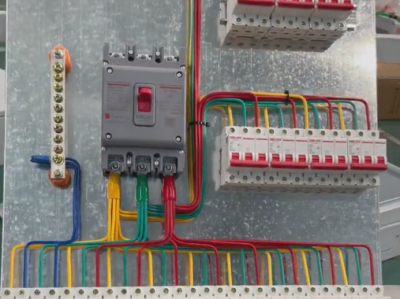

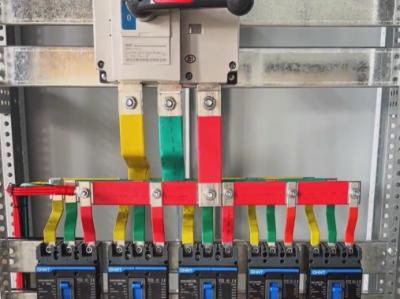

- **Circuit breaker**:

As the main protection and control component, it is used to cut off and connect the circuit. Common ones are molded case circuit breakers and miniature circuit breakers, which can be selected according to different rated currents and application scenarios. For example, molded case circuit breakers are suitable for the protection of circuits with large currents, while miniature circuit breakers are often used for the protection of branch circuits or small loads.

- **Contactor**:

Mainly used to control the start, stop and forward and reverse operations of loads such as motors. Through the action of electromagnetic force, it closes or opens the contacts to realize the control of the circuit. Contactors have the characteristics of large control capacity and high operating frequency.

- **Thermal relay**:

Used for overload protection and works on the principle of the thermal effect of current. When the current in the circuit exceeds the rated value for a certain period of time, the bimetallic strip inside the thermal relay will be bent and deformed, thereby triggering its normally closed contact to open and cut off the circuit to protect the load equipment.

- **Fuse**:

When a short circuit occurs in the circuit, the fuse element of the fuse melts and quickly cuts off the current to play a role in short-circuit protection. The fuse element material and rated current need to be selected according to the specific situation of the circuit.

- **Current transformer and voltage transformer**:

The current transformer is used to transform a large current into a small current for use by ammeters and relay protection devices; the voltage transformer transforms a high voltage into a low voltage for use by voltmeters and protection devices.

- **Measuring instruments**:

Including ammeters, voltmeters, electric energy meters, etc. The ammeter is used to measure the current magnitude in the circuit, the voltmeter measures the voltage magnitude, and the electric energy meter is used to measure electric energy consumption and provide a basis for electricity bill calculation.

**III. Characteristics**

1. **Advantages of drawer structure**

- **Convenient for maintenance and repair**:

The drawer unit can be easily pulled out, which is convenient for the maintenance or replacement of a single functional unit without affecting the normal operation of other units. For example, in a power distribution system with multiple branches, if the electrical components of a certain branch fail, only the corresponding drawer needs to be pulled out for repair without powering off the entire switchgear.

- **High flexibility**:

The number and types of drawer units can be flexibly configured according to actual needs to meet the requirements of different loads and functions. For example, in the power distribution system of a factory, drawer units with different capacities and functions can be configured according to the power consumption needs of different workshops or equipment.

2. **High reliability**

- Due to the partitioned design inside the cabinet, each compartment is independent of each other, which can effectively prevent the spread of faults between different units. At the same time, its electrical components are strictly selected and quality-controlled to ensure the reliability of the equipment during long-term operation.

3. **High degree of standardization**

- The GCS switchgear is designed and manufactured in accordance with certain standards. Its cabinet size, electrical component installation methods, etc. all have unified standards. This makes the GCS switchgear produced by different manufacturers interchangeable to a certain extent, which is convenient for users to update and expand equipment.

**IV. Application Fields**

1. **Industrial field**

- Widely used in various industrial enterprises, such as machinery manufacturing, chemical industry, metallurgy and other industries. Provide stable power distribution, control and protection for production equipment to ensure the normal progress of industrial production. For example, in a machinery manufacturing workshop, provide power support and protection for equipment such as lathes, milling machines, and drilling machines.

2. **Commercial buildings**

- Applicable to low-voltage power distribution systems of commercial buildings such as shopping malls, hotels, and office buildings. It can meet the power needs of a large number of electrical equipment such as lighting, air conditioning, elevators, and office equipment in these places, and provide reliable protection and control functions.

3. **Data centers**

- Provide power distribution and protection for equipment such as servers, air conditioners, and UPS in data centers. Due to the extremely high reliability requirements for power supply in data centers, the protection function and reliability of GCS switchgear can meet its needs and ensure the stable operation of data centers.

**V. Installation and Maintenance**

1. **Installation requirements**

- **Environmental requirements**

- It should be installed in a dry and well-ventilated place and avoid being installed in an environment with high humidity, corrosive gases or severe dust. A humid environment may cause damage to electrical components due to moisture, and corrosive gases and dust will erode components and cabinets and affect the service life of the equipment.

- **Foundation requirements**

- A solid installation foundation is required. Generally, channel steel or concrete foundation is used. When the cabinet body is installed on the foundation, the levelness and verticality must be ensured. The levelness deviation should not exceed 1.5‰, and the verticality deviation should not exceed 1.5‰ to ensure the stability of the cabinet body and the normal operation of electrical components.

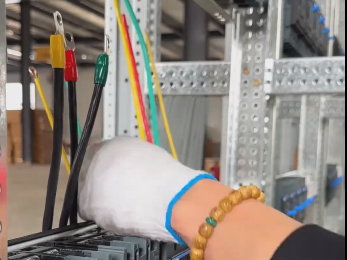

- **Wiring requirements**

- The incoming and outgoing cables should be laid according to the design requirements. The cable connection should be firm and reliable, and good markings should be made. The cross-sectional area of the cable should be selected according to the rated current of the circuit to avoid problems such as heating due to too thin cables.

2. **Maintenance points**

- **Regular inspection**

- Regularly (such as monthly or quarterly) inspect the GCS switchgear to check whether the connections of electrical components are loose, whether the measuring instruments are working properly, and whether the drawers are inserted and removed smoothly.

- **Cleaning work**

- Regularly clean the dust inside and outside the cabinet body, because excessive dust accumulation may affect the heat dissipation and insulation performance of electrical components. For drawer units, also clean the drawer rails to ensure good insertion and removal of drawers.

- **Component testing**

- Regularly perform function tests on electrical components such as circuit breakers and contactors, such as testing whether the opening and closing actions of circuit breakers are normal and whether the closing and releasing of contactors are normal. When necessary, also check and calibrate the setting values of protection components such as thermal relays to ensure the accuracy and reliability of their protection functions.