Distribution Cabinet with Chint Dual-Power Switch

Product description

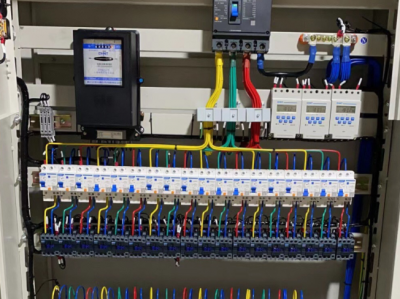

A distribution cabinet equipped with a Chint dual-power switch is a power distribution device integrated with automatic dual-power switching functionality. It is primarily used in scenarios requiring **high-reliability power supply**, such as hospitals, data centers, high-rise buildings, and industrial plants. Through the dual-power switch (ATSE), it enables automatic or manual switching between two power sources (e.g., main power and backup power) to ensure uninterrupted power supply to loads during power failures. Below is a detailed analysis of such distribution cabinets:

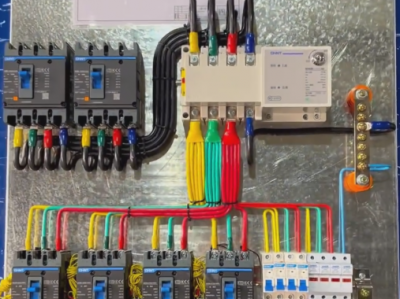

*I. Core Components and Functions*Chint NXC-75/220V AC contactor*

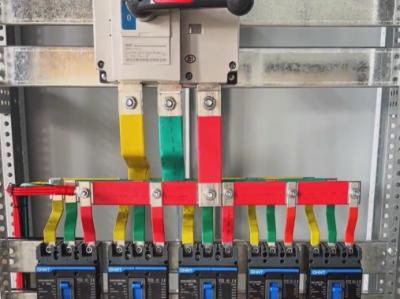

*1. Chint Dual-Power Switch (ATSE)**

- **Role**: Monitors parameters such as voltage and frequency of two power sources (normal power and backup power). When the normal power fails (e.g., power outage, voltage abnormality), it automatically switches to the backup power to prevent load power failure.

- **Types**:

- **PC Type**: Adopts an integrated structure with fast switching speed (≤100ms) and short-circuit current withstand capability, suitable for scenarios with high switching time requirements (e.g., fire protection loads).

- **CB Type**: Composed of two circuit breakers and a controller, with overload and short-circuit protection functions, suitable for power distribution systems requiring protective features.

- **Switching Modes**:

- **Auto-Transfer and Auto-Revert**: Automatically switches back to the normal power source once it recovers (suitable for non-continuous backup scenarios).

- **Auto-Transfer without Auto-Revert**: Requires manual switching back to the normal power source after switching to the backup power (suitable for critical loads requiring backup power locking).

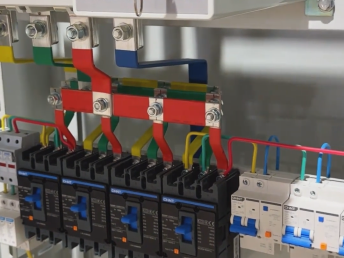

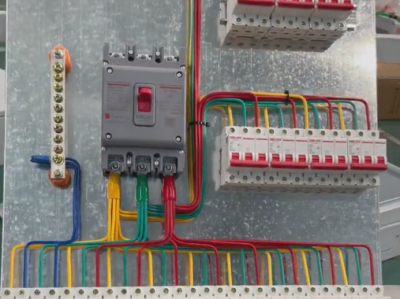

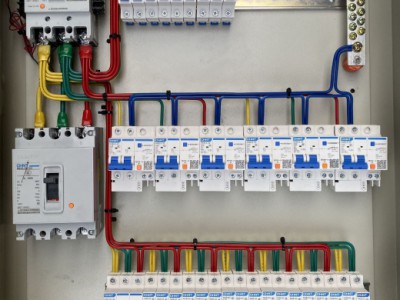

*2. Other Components of the Distribution Cabinet**

- **Circuit Breakers**: Control each branch power supply, with overload and short-circuit protection functions (e.g., Chint NM series molded case circuit breakers).

- **Contactors/Relays**: Coordinate with the dual-power switch for automatic control or remote monitoring (e.g., linkage with PLC or intelligent systems).

- **Instruments and Indicators**: Display voltage, current, and power status (e.g., normal/backup power indicators, switching status indicators).

- **Lightning Protection Module** (Optional): Prevents surge voltage impacts and protects equipment safety.

- **Intelligent Monitoring Module** (Optional): Supports RS485 communication for remote monitoring of distribution cabinet operation data (e.g., voltage, current, switching records).

*II. Typical Application Scenarios**

1. **Fire Protection Systems**:

- Fire pumps, emergency lighting, smoke exhaust fans, and other fire protection loads require dual-power supply to ensure reliable system operation during fires (complying with GB50016 fire protection codes).

2. **Data Centers/Hospitals**:

- Servers and medical equipment cannot tolerate power outages. Dual-power switching avoids data loss or medical accidents caused by mains power failures.

3. **High-Rise Buildings/Commercial Complexes**:

- Important loads such as elevators, water pumps, and public lighting use dual-power supply to enhance power supply stability.

4. **Industrial Production Lines**:

- Continuously operating equipment (e.g., chemical and pharmaceutical production lines) requires dual-power保障 to reduce downtime losses.

*III. Working Principle and Wiring Schematic**

*1. Working Principle**

1. **Normal Operation**: The normal power source (e.g., mains power) supplies power, and the dual-power switch is in the "normal power closed" state, with the backup power source (e.g., generator, another mains supply) on standby.

2. **Power Failure**: When the normal power voltage drops below the set threshold (e.g., below 70% of the rated voltage), the controller triggers the switching logic, disconnects the normal power circuit breaker, closes the backup power circuit breaker, and switches the load to the backup power supply.

3. **Power Recovery** (Auto-Transfer and Auto-Revert Mode): Once the normal power recovers, the controller automatically switches the load back to the normal power source, and the backup power returns to standby.

*2. Typical Wiring Schematic**

```

[Normal Power Inlet] → [Normal Side of Dual-Power Switch] → [Circuit Breaker 1] → [Branch Load 1]

↓

[Backup Power Inlet] → [Backup Side of Dual-Power Switch] → [Circuit Breaker 2] → [Branch Load 2]

↓

[Controller] → [Indicators/Remote Monitoring Interface]

```

*IV. Installation and Commissioning Key Points**

*1. Pre-Installation Preparations**

- **Environmental Requirements**: Install in a dry, ventilated area free of corrosive gases, away from heat sources and vibration sources.

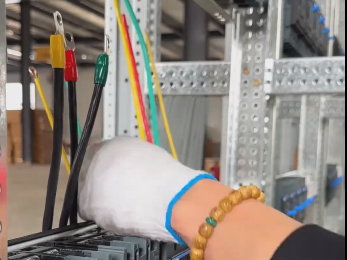

- **Line Inspection**: Ensure the phase sequence of the normal and backup power sources is consistent (to avoid equipment damage due to phase sequence errors), and the conductor specifications meet the load current requirements.

- **Grounding Requirements**: The distribution cabinet must be reliably grounded (PE line) with a grounding resistance ≤4Ω to ensure leakage safety.

*2. Installation Steps**

1. Fix the distribution cabinet on the foundation channel steel or wall bracket to ensure it is level and secure.

2. Connect the normal and backup power inlets (note the distinction between live wires, neutral wires, and ground wires).

3. Connect the load outlets to ensure the branch circuit breakers match the load power (e.g., 16A circuit breakers for air conditioning circuits, 10A for lighting circuits).

4. After wiring, check that all terminal screws are tight to avoid heat generation due to poor contact.

*3. Commissioning and Testing**

- **Manual Switching Test**: Disconnect the normal power source, manually operate the dual-power switch to switch to the backup power source, and observe whether the indicators and load operation are normal.

- **Automatic Switching Test**: Simulate a normal power failure (e.g., disconnect the normal power circuit breaker) and observe whether it automatically switches to the backup power source within the set time (e.g., 1-3 seconds).

- **Parameter Setting** (if equipped with intelligent modules): Set voltage and frequency thresholds, switching delay time, communication protocols, etc. (refer to the Chint product manual).

*V. Maintenance and Fault Handling**

*1. Routine Maintenance**

- **Regular Inspections**: Monthly checks of indicator status, tightness of wiring terminals, cabinet heating, and dust removal inside.

- **Contact Maintenance**: Annual inspection of whether the contacts of the dual-power switch are oxidized or burnt, and polish with fine sandpaper or replace components if necessary.

- **Function Testing**: Quarterly manual/automatic switching tests to ensure the switching mechanism is flexible and reliable.

*2. Common Faults and Solutions**

| Fault Phenomenon | Possible Causes | Solutions |

| No Power Switching | Controller power failure, incorrect detection threshold settings | Check controller power supply and reset voltage/frequency thresholds. |

| Load Tripping After Switching | Abnormal backup power voltage, load-side short circuit | Test backup power parameters and inspect load lines. |

| Severe Contact Heating | Loose wiring, poor contact | Tighten terminals, clean or replace contacts. |

| Abnormal Indicators | Bulb failure, circuit open | Replace indicators and check control circuit continuity. |

*VI. Advantages of Chint Dual-Power Distribution Cabinets**

1. **High Reliability**: Uses renowned brand components, passes 3C certification, and complies with national standards such as GB/T 14048.11.

2. **Intelligent Upgrades**: Supports IoT integration (e.g., Chint Kunlun series) for remote monitoring of power status and fault early warning.

3. **Flexible Configuration**: Customizable switching time and protection functions (e.g., leakage protection, over-voltage/under-voltage protection) based on requirements.

4. **Cost-Effective**: More price-competitive than imported brands, with a wide coverage of after-sales service networks.

*VII. Selection Recommendations**

1. **Choose Based on Load Type**:

- **Fire Protection Loads**: Prioritize PC-type dual-power switches with a switching time ≤1.5 seconds to comply with fire protection codes.

- **Sensitive Electronic Equipment**: Select models with surge protection and intelligent monitoring to avoid voltage fluctuations affecting equipment.

2. **Calculate Rated Current**: The rated current of the dual-power switch must be ≥1.2 times the total load current (e.g., select a 100A switch for a total load current of 80A).

3. **Consider Backup Power Type**: If the backup power is a generator, configure a "generator start signal" interface to ensure the generator starts and stabilizes before switching.

The distribution cabinet with a Chint dual-power switch is a core device to ensure continuous power supply for critical loads. Its design, installation, and maintenance must strictly follow electrical codes. It is recommended to communicate with Chint's technical team or professional electricians at the project's initial stage to customize solutions based on actual needs, ensuring safe and reliable system operation.