Low voltage switchgear

Product description

*I. Definition**

*I. Definition**

1. **Definition**

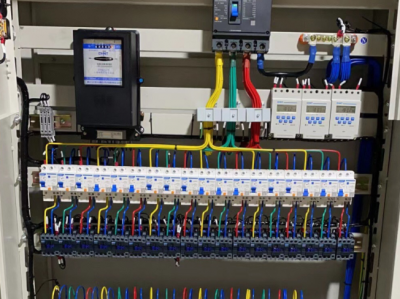

- The Low voltage switchgear is an electrical equipment used for distributing electric energy, controlling, protecting, and monitoring circuits. It is mainly applied in low-voltage power distribution systems with a rated voltage of less than 1000V.

2. **Functions**

- **Power distribution**

- Reasonably distribute the electric energy from power supply equipment such as transformers to various branches to meet the power consumption needs of different loads. For example, in a factory, distribute the electric energy of the total power supply to the electrical equipment in different areas such as various workshops and offices.

- **Circuit control** - Realize the on-off control of the circuit through electrical components such as circuit breakers and contactors. For example, it can control the on-off of the lighting circuit and disconnect the circuit when lighting is not needed to save electric energy.

- **Protection function** - Includes overload protection, short-circuit protection, undervoltage protection, etc. When an overload current occurs in the circuit (such as when too many devices are running simultaneously, resulting in excessive current), the overload protection device (such as a thermal relay) will automatically cut off the circuit to prevent the equipment from being damaged due to overheating; in the event of a short circuit, the fuse or circuit breaker acts quickly to avoid the fault from expanding and affecting the entire power distribution system; undervoltage protection protects the equipment when the voltage is too low to prevent the equipment from working abnormally and being damaged under low voltage.

- **Monitoring function**

- Monitor parameters such as current, voltage, and electric energy in the circuit with measuring instruments such as ammeters, voltmeters, and electric energy meters. This is convenient for operation and maintenance personnel to understand the circuit operation status in time. For example, judge whether there is abnormal current in a certain branch by observing the ammeter value.

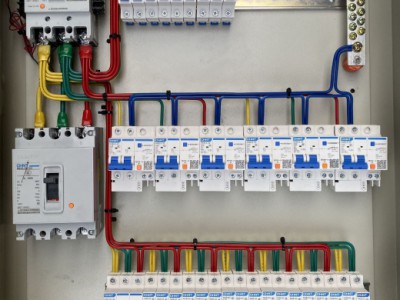

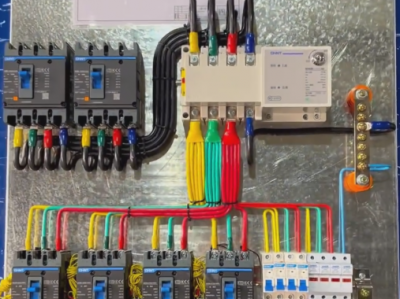

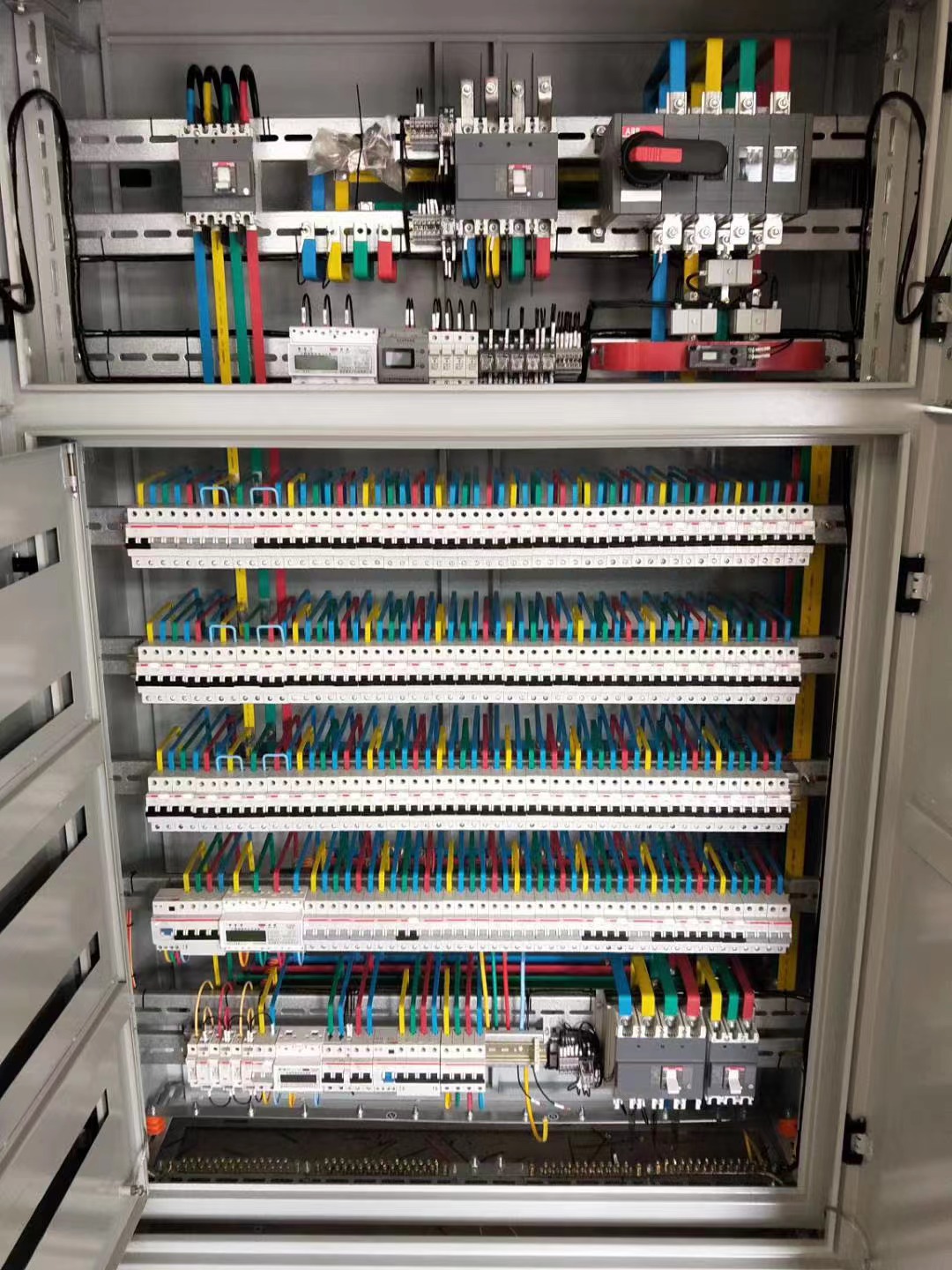

**II. Structural composition**

1. **Cabinet body**

- It is the shell of the Low voltage switchgear and plays a role in protecting the internal electrical components and the safety of operators. The cabinet body is generally made of metal materials such as cold-rolled steel plates and has sufficient strength and rigidity. The cabinet structure design should consider factors such as ventilation and heat dissipation and protection level. Protection levels such as IP30, IP40, etc. IP30 indicates that it can prevent solid foreign matters with a diameter greater than 2.5mm from entering. The higher the protection level, the stronger the protection ability against dust, water, and foreign matters.

2. **Electrical components**

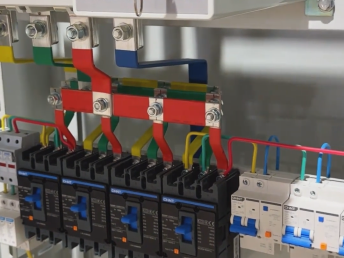

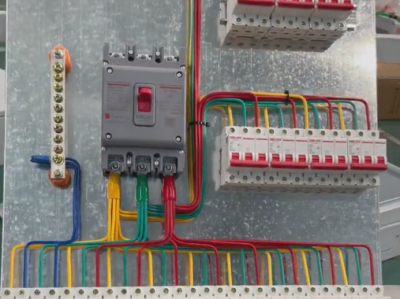

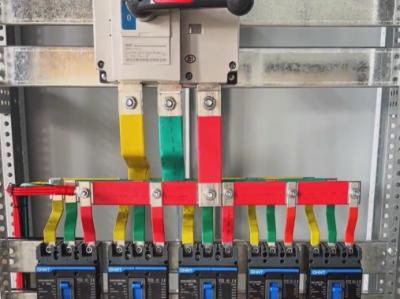

- **Circuit breaker**

- It is one of the most important protection and control components in the Low voltage switchgear. It can automatically cut off the circuit when faults such as overload, short circuit, and undervoltage occur in the circuit. At the same time, it can also be manually operated to realize the on-off control of the circuit. Common ones are air circuit breakers, molded case circuit breakers, etc. Different types are suitable for different current ranges and application scenarios.

- **Contactor**

- It is mainly used to frequently connect and disconnect circuits and is usually used to control loads such as motors. It controls the closing and opening of contacts through electromagnetic force and has the advantages of large control capacity and remote operation.

- **Thermal relay**

- Used for overload protection. It uses the principle of the thermal effect of current. When the current in the circuit exceeds the rated value for a certain period of time, the bimetallic strip inside the thermal relay will be heated and bent, thereby triggering its normally closed contact to open and cut off the circuit to protect the load equipment.

- **Fuse** - When a short circuit occurs in the circuit, the fuse element melts and quickly cuts off the current, playing a role in short-circuit protection. The fuse element material and rated current are selected according to the circuit requirements.

- **Current transformer and voltage transformer**

- The current transformer is used to transform a large current into a small current for use by ammeters and relay protection devices; the voltage transformer transforms a high voltage into a low voltage for use by voltmeters and protection devices.

- **Measuring instruments**

- Such as ammeters, voltmeters, electric energy meters, etc. The ammeter is used to measure the current magnitude in the circuit, the voltmeter measures the voltage magnitude, and the electric energy meter is used to measure electric energy consumption.

**III. Common types**

1. **Fixed panel switchgear**

- The structure is simple. Usually, there is a protective panel on the front, and electrical components are installed in the cabinet behind the panel. This type of switchgear has a relatively low protection level and is not very convenient to operate. It is mainly suitable for places with low protection requirements and simple loads, such as simple power distribution in small factories. 2.

**Drawer-type switchgear**

- The electrical components of each circuit are installed in drawer-type units and can be easily pulled out for inspection and maintenance without affecting the normal operation of other circuits. It has a relatively high protection level and better operation safety. It is widely used in places with high requirements for power supply reliability and frequent inspection and maintenance, such as power distribution systems in large shopping malls, hospitals, and other places.

3. **Combined switchgear**

- It is composed of multiple standard units and can flexibly configure different functional units according to user needs, such as incoming line units, outgoing line units, metering units, etc. This type of switchgear has strong flexibility and expandability and is suitable for low-voltage power distribution systems with various scales and functional requirements.

**IV. Installation and maintenance**

1. **Installation requirements**

- **Environmental requirements**

- It should be installed in a dry and well-ventilated place and avoid being installed in an environment with high humidity, corrosive gases, or severe dust. If the environmental humidity is high, it may cause the electrical components to be damaged by moisture; corrosive gases will corrode the cabinet body and components and affect their service life.

- **Installation foundation**

- A firm installation foundation is required. Generally, channel steel is used to make the foundation frame. When the cabinet body is installed on the foundation frame, the levelness and verticality must be ensured. The levelness deviation should generally not exceed 1.5‰, and the verticality deviation should not exceed 1.5‰ to ensure the stability of the cabinet body and the normal operation of electrical components.

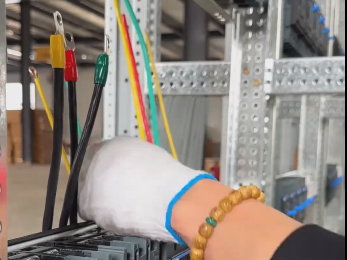

- **Wiring requirements**

- The incoming and outgoing cables should be laid according to the design requirements. Ensure that the cable connections are firm and reliable, and make good markings. The cross-sectional area of the cable should be selected according to the rated current of the circuit to avoid problems such as heating due to too thin cables.

2. **Maintenance points**

- **Regular inspection**

- Regularly (such as monthly or quarterly) inspect the Low voltage switchgear to check whether the connections of electrical components are loose, whether the measuring instruments are working properly, and whether the protective door of the cabinet body is closed properly.

- **Cleaning work**

- Regularly clean the dust inside and outside the cabinet body because excessive dust accumulation may affect the heat dissipation and insulation performance of electrical components. For drawer-type switchgear, also clean the drawer rails to ensure smooth insertion and removal of drawers.

- **Component testing**

- Regularly perform functional tests on electrical components such as circuit breakers and contactors, such as testing whether the opening and closing operations of circuit breakers are normal and whether the closing and releasing of contactors are normal. When necessary, also check and calibrate the setting values of protection components such as thermal relays to ensure the accuracy and reliability of their protection functions.