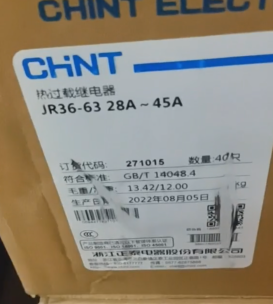

Chint Thermal Overload Relay JR36-63/28A-45A

Product description

The Chint Thermal Overload Relay JR36-63/28A-45A is a device specifically designed for industrial motor protection. It is suitable for three-phase motors with an AC frequency of 50/60Hz and a voltage of up to 690V, providing overload and phase-failure protection functions. The following is a detailed analysis of its core information:

I. Core Specifications and Functions

1. Electrical Parameters

- **Frame Current**: 63A; **Setting Current Range**: 28-45A. It can be continuously adjusted via a knob to match the rated current of the motor.

- **Voltage Rating**: Supports AC 690V, meeting the requirements of most industrial environments.

- **Trip Class**: Class 10A, ensuring rapid response in case of overload (usually tripping within 2 minutes).

2. Protection Mechanisms

- **Bimetallic Strip Thermal Protection**: Current is monitored through a heating element. When an overload occurs, the bimetallic strip bends to trigger the contacts and cut off the circuit.

- **Differential Phase-Failure Protection**: When any phase loses power, the relay acts immediately to prevent the motor from being burned due to single-phase operation.

- **Temperature Compensation**: Maintains stable operating characteristics within an ambient temperature range of -5℃ to +40℃, avoiding false tripping caused by ambient temperature fluctuations.

3. Operational Characteristics

- **Manual/Auto Reset**: The reset mode can be switched via an adjustment knob. The auto-reset time is approximately 5 minutes, while manual reset requires pressing the reset button.

- **Test Button**: Can simulate an overload condition to test the contact action, ensuring the relay functions properly.

II. Application Scenarios and Matching Solutions

1. Typical Applications

- **Industrial Motor Protection**: Suitable for three-phase asynchronous motors in scenarios such as factories, mines, and construction sites, covering a power range of approximately 15-22kW (specific motor parameters should be considered).

- **Matching with Magnetic Starters**: Can be combined with Chint CJT1 series contactors to form a QC36-type magnetic starter, realizing a complete motor control and protection system.

2. Installation Requirements

- **Independent Installation**: Fixed with M5/M6 screws, the inclination of the installation surface should not exceed 5°, and it should be kept away from environments with severe vibration and impact.

- **Wiring Specifications**: The main circuit is connected to three-phase live wires (incoming lines L1-L2-L3, outgoing lines T1-T2-T3), and the auxiliary contacts (95-96 normally closed, 97-98 normally open) are connected to the control circuit.

- **Wire Specifications**: For the main circuit, it is recommended to use 6-16mm² single-core wires; for the auxiliary circuit, 0.5-1mm² wires are used.

III. Certifications and Compliance

1. Domestic Certifications

Certified by the China Quality Certification Center (CQC), complying with the standards of GB 14048.4 and GB 14048.5.

2. International Standards

Meets the requirements of IEC 60947-4-1 and is suitable for export equipment. However, UL or CSA certifications are not clearly marked. If it is to be used in the North American market, it is recommended to contact the manufacturer to confirm whether there is a customized version.

IV. Alternative Solutions and Selection Recommendations

1. Same-Brand Alternatives

- If the setting current range needs to be expanded, other specifications of the JR36-63 series (e.g., 40-63A) can be considered, or an upgrade to the JR36-160 series (covering 75-160A) can be made.

- When matching with a CJT1 contactor, it is recommended to select the CJT1-60 model to ensure compatibility.

2. International Brand Alternatives

- **Schneider**: Tesys D series LRD21C (setting range 28-45A) or LRD22C (32-50A). Attention should be paid to whether the installation dimensions are compatible.

- **Siemens**: 3UA59 series (e.g., 3UA59 22-50A), which supports DIN rail installation and is suitable for renovation projects.

V. Maintenance and Troubleshooting

1. Daily Maintenance

- Regularly clean the dust on the housing and check whether the terminal blocks are loose.

- Conduct an action test at least once a year to ensure the sensitivity of the bimetallic strip is normal.

2. Common Fault Handling

- **Relay Fails to Act**: Check if the setting current is too high, if the contacts are oxidized, or if the heating element is burned out (replacement is required if so).

- **Frequent False Tripping**: May be caused by excessively low setting current, poor wire contact, or excessively high ambient temperature; these factors need to be checked one by one.

- **Abnormal Reset**: If manual reset is ineffective, try powering off and re-operating; if auto-reset fails, it may be due to spring fatigue, and the relay needs to be replaced.

VI. Precautions

1. Environmental Conditions

Avoid using it in environments where the humidity exceeds 90% (at 25℃) or the altitude is higher than 2000m, otherwise its performance may be affected.

2. Selection Principles

The setting current should be set to 1.05-1.1 times the rated current of the motor; for short-term impact loads (such as motor starting), it can be appropriately relaxed to 1.2 times.

3. Safe Operation

Power must be cut off before wiring; when replacing the relay, ensure that the model matches to avoid protection failure due to inconsistent parameters.

Summary

With its stable performance, flexible reset mode, and comprehensive protection functions, the JR36-63/28A-45A has become an ideal choice for industrial motor protection. The combined solution of this relay with the CJT1 contactor can efficiently realize motor control, and the designs of temperature compensation and phase-failure protection further improve its reliability. If it is to be used in the North American market, it is recommended to first confirm the certification status or select alternative models of international brands. During use, strictly following the installation specifications and conducting regular maintenance are the keys to ensuring the long-term stable operation of the equipment