Chint NXC-75/220V AC contactor

Product description

The Chint NXC-75/220V AC contactor is a commonly used industrial-grade control device suitable for controlling three-phase loads with a rated current of 75A and a coil voltage of 220V. Below is a detailed analysis of this contactor model:

The Chint NXC-75/220V AC contactor is a commonly used industrial-grade control device suitable for controlling three-phase loads with a rated current of 75A and a coil voltage of 220V. Below is a detailed analysis of this contactor model:

*I. Basic Parameters and Specifications*Schneider LC1DN3210 and Chint NXC32 contactors*

1. **Rated Parameters*Chint DC Contactor NC1-5011-36V*

- **Model Meaning**: NXC-75 (design series)/220V (coil voltage)

- **Rated Current**: 75A (can control 37kW three-phase motors under AC-3 usage category)

- **Coil Voltage**: 220V AC (50/60Hz)

- **Pole Configuration**: 3 poles (main contacts) + 2 normally open (NO) + 2 normally closed (NC) auxiliary contacts

- **Mechanical Life**: 10 million operations

- **Electrical Life**: 1 million operations (AC-3 category)

2. **Application Scenarios*Wiring of Delixi AC Contactor*

- Start, stop, and forward/reverse control of three-phase motors

- On/off control of electric heating equipment and lighting circuits

- Combined with thermal relays to form motor protection circuits

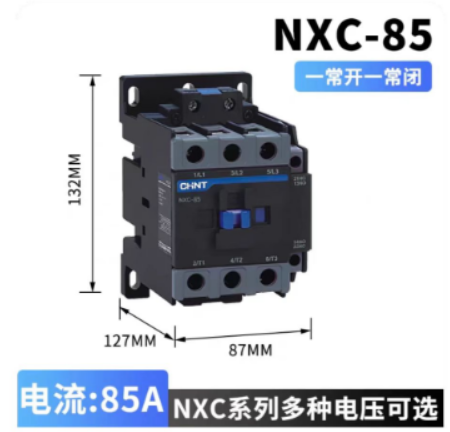

*II. Core Structure and Terminal Description*CHINT AC contactor CJX2*

*1. Appearance and Components**

*(Schematic diagram; actual product may vary)*

*2. Terminal Layout**

| Terminal Type | Identification/Number | Function Description |

| Main Contacts | L1/T1, L2/T2, L3/T3 | Three-phase power input/output (L1-L3 for power supply, T1-T3 for load) |

| Coil Terminals | A1, A2 | 220V coil power supply (A1 to live wire, A2 to neutral wire) |

| Auxiliary Contacts | 13/14 (NO), 21/22 (NC) | Control circuit signal feedback (NO/NC) |

| Thermal Relay Interface | 95/96, 97/98 | Connect to thermal relay for overload protection |

*III. Typical Application Wiring Diagrams**

*Scenario 1: Direct Start Control of Three-Phase Motor**

```

┌─────────────────────────────────┐

│ Circuit Breaker (Q) │

│ ┌───┐ ┌───┐ │

│ L1 ──────┤ │───┤ ├───┬─────┘

│ │ │ │ │ │

│ L2 ──────┤ │───┤ ├───┼─────┐

│ └───┘ └───┘ │ │

│ │ │

│ ┌───┐ ┌───┐ │ │

│ L3 ──────┤ │───┤ ├───┴─────┘

│ └───┘ └───┘

│ │ │

│ ┌──────┴───────┴──────┐

│ │ Contactor Main Contacts │

│ │ (L1/T1-L3/T3) │

│ └──────┬───────┬──────┘

│ │ │

│ ┌───┐ ┌───┐

│ T1 ──────┤ │ │ │──── Motor U Phase

│ │ │ │ │

│ T2 ──────┤ │ │ │──── Motor V Phase

│ │ │ │ │

│ T3 ──────┤ │ │ │──── Motor W Phase

│ └───┘ └───┘

│

│ ┌───────────────┐

│ │ Control Circuit │

│ │ │

│ │ ┌───┐ ┌───┐ │

│ └──┤SB1├──┤KM ├──┘

│ │ │ │

└───┘ └───┘

Stop Coil A1

│

│

└───────────┐

│

│

┌───┐

│ │

│ │

└───┘

A2

│

│

└──── Neutral Wire N

```

**Explanation**:

- Circuit Breaker (Q): Protects the circuit from overloads and short circuits

- Contactor (KM): Main contacts control motor power supply; coil A1/A2 connected to 220V

- Start Button (SB1): When pressed, the coil is energized, main contacts close, and the motor starts

*Scenario 2: Motor Control with Overload Protection**

```

┌─────────────────────────────────┐

│ Circuit Breaker (Q) │

│ ┌───┐ ┌───┐ │

│ L1 ──────┤ │───┤ ├───┬─────┘

│ │ │ │ │ │

│ L2 ──────┤ │───┤ ├───┼─────┐

│ └───┘ └───┘ │ │

│ │ │

│ ┌───┐ ┌───┐ │ │

│ L3 ──────┤ │───┤ ├───┴─────┘

│ └───┘ └───┘

│ │ │

│ ┌──────┴───────┴──────┐

│ │ Contactor Main Contacts │

│ │ (L1/T1-L3/T3) │

│ └──────┬───────┬──────┘

│ │ │

│ ┌───┐ ┌───┐

│ T1 ──────┤ │ │ │──── Thermal Relay (FR)─┐

│ │ │ │ │ │

│ T2 ──────┤ │ │ │ │

│ │ │ │ │ │

│ T3 ──────┤ │ │ │ │

│ └───┘ └───┘ │

│ │

│ │

│ ┌──────────┴──────────┐

│ │ Motor │

│ └────────────────────┘

│

│ ┌──────────────────────────────────┐

│ │ Control Circuit │

│ │ │

│ │ ┌───┐ ┌───┐ ┌─────┐ ┌───┐ │

│ └──┤SB1├──┤SB2├──┤FR NC├──┤KM ├──┘

│ │ │ │ │ │ │ │

└───┘ └───┘ └─────┘ └───┘

Stop Start Overload Protection Coil A1

│

│

└───────────┐

│

│

┌───┐

│ │

│ │

└───┘

A2

│

│

└──── Neutral Wire N

```

**Explanation**:

- Thermal Relay (FR): Connected to the main circuit via terminals 95/96; NC contacts 97/98 are wired in series in the control circuit

- During overload, the bimetallic strip in FR heats and bends, opening the NC contacts, de-energizing the contactor coil, and stopping the motor

*IV. Installation and Usage Precautions**

1. **Environmental Requirements**

- Temperature Range: -5°C ~ +40°C

- Humidity: ≤95%RH (no condensation)

- Altitude: ≤2000 meters

2. **Installation Steps**

- Install vertically to maintain heat dissipation space

- Use M8 bolts for main circuit terminals, tightening torque 8-10N·m

- Use 0.75-2.5mm² wires for control circuits to ensure good contact

3. **Maintenance Key Points**

- Regularly clean oxide layers on contact surfaces

- Check for loose bolts (at least once a year)

- Coil temperature rise should not exceed 65K (at 40°C ambient temperature)

*V. Common Faults and Solutions**

| Fault Phenomenon | Possible Causes | Solutions |

| Coil not energizing | Power not connected, coil burned out, mechanical jamming | Check voltage, replace coil, clean components |

| Contact overheating | Poor contact, excessive load, contact oxidation | Tighten terminals, reduce load, polish contacts |

| Not releasing after power-off | Residual magnetism in core, contact adhesion | Replace core, clean or replace contacts |

| Excessive noise | Broken core short-circuit ring, voltage fluctuations | Replace core, stabilize power supply voltage |

*VI. Selection Alternatives**

If NXC-75 is out of stock, consider the following alternative models:

- **Schneider LC1-D75**: Same specifications, strong compatibility

- **Siemens 3TF52**: Higher reliability, suitable for critical applications

- **ABB A9-40/75**: Modular design, easy to expand

**Note**: When replacing, confirm that coil voltage, contact capacity, and installation dimensions are consistent.

Summary**

The Chint NXC-75/220V AC contactor is a reliable industrial control component that can effectively manage three-phase loads through proper wiring and maintenance. Before use, verify power supply compatibility and prioritize control circuits with overload protection to extend equipment life and ensure safety.